Rugged & Durable

Built with high-strength steel and branded components to withstand tough road conditions

Kales rear dump semi-trailers are equipped with 214 mm hydraulic cylinders, which provide both powerful performance and excellent quality, ensuring that tipping accidents do not happen.

The rear box panel of the trailer is supported by four flipping brackets, ensuring the cargo is more secure. The suspension of the Kales rear dump semi-trailer is reinforced at multiple points. The trailer floor is 10 mm thick, and the central pin has a diameter of 70 mm, all of which enhance the trailer’s stability. The new dump truck is fitted with high-quality, famous brand lading gear that last for over 10 years.

Value for Money: From Standard 60T to Mining 100T.

Kales rear dump semi-trailers offer exceptional quality at a competitive price. Standard equipped with 214mm Hydraulic Cylinders and a 10mm Reinforced Floor, they are designed to last over 10 years. Now available with premium upgrades: Air Suspension, WABCO EBS, and SAF/BPW Axles for global fleets.

Even our standard models outperform the competition. We retain all the robust features that made Kales famous:

Ribbed Structure with 10mm Floor & 4 Brackets

Beyond our standard specs, we offer tailored chassis reinforcement for extreme mining conditions:

Reinforced Suspension for 80T+ Loads

For customers requiring easier global maintenance or superior driving comfort, we now offer these premium upgrades:

In addition to our durable KALES axles, you can choose BPW (Germany), SAF (Germany), or FUWA. This ensures you can find spare parts anywhere in the world.

Air Suspension: Provides superior shock absorption and ride quality.

Mechanical Suspension: Reinforced at multiple points for extreme durability on rough terrain.

Standard with WABCO ABS. Upgrade to WABCO EBS (Electronic Braking System) for faster response times and anti-rollover stability.

Full set of HYVA lifting cylinders (or comparable top brand) designed to last over 10 years.

| Feature | Specification Details |

|---|---|

| External Dimension | 8,112 × 2,500 × 3,482 mm (Customizable) |

| Total Volume | 35 Cubic Meters (m³) (Standard) |

| Payload Capacity | 50T – 60T (Standard) / 80T – 100T (Mining Version) |

| Lifting System | HYVA Hydraulic Cylinder (214mm Wide Cylinder) |

| Box Material | Floor: 10mm-14mm / Side: 8mm-10mm High Tensile Steel |

| Rear Gate | Reinforced with 4 Flipping Brackets |

| Axles | 3 or 4 Axles – BPW / SAF / FUWA / KALES |

| Suspension | Mechanical (Reinforced 70mm Pin) or Air Suspension |

| Braking System | WABCO Brand (ABS Standard / EBS Optional) |

| Tires | 12R22.5 / 315/80R22.5 (12 or 16 Units) |

| King Pin | JOST 2.0″ (50#) or 3.5″ (90#) – Bolted/Welded |

| Landing Gear | JOST Brand D200T (High-quality, long-life gear) |

Heavy Duty Rear Gate

12R22.5 Heavy Duty Tires

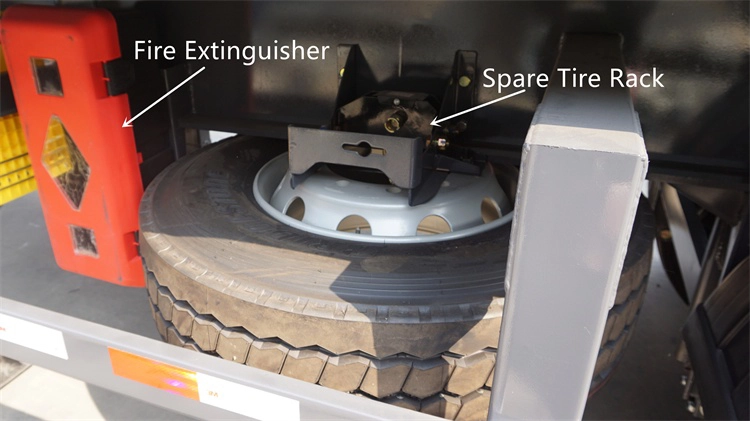

Accessories & Spare Tire

Q1: Why do you use 4 flipping brackets instead of 2?

A: Standard trailers use 2, but for heavy loads like rocks, this is often insufficient. We use 4 flipping brackets to distribute the stress evenly on the rear gate, preventing deformation and ensuring cargo security during dumping.

Q2: Can I choose Air Suspension for a dump trailer?

A: Yes. While mechanical suspension is standard for extreme rough roads, Air Suspension offers better shock absorption and protection for the chassis, especially if you are hauling on mixed road conditions.

Q3: Can this trailer handle 100 tons?

A: Yes. For 100-ton mining requirements, we upgrade the floor to 14mm, add a 4th axle, and triple-reinforce the main beam. Just let us know your load, and we will build it.

Low Price, Great Quality, Long-Term Reliability.

Covers hydraulic system, main beam, and axles.

No middlemen. You get the best price for high-quality specs.

Wax sprayed or tarp covered for sea transport protection.

Whether standard 60T or Mining 100T, we have the spec for you.

www.kalestruck.com | Professional Semi Trailer Manufacturer

0 comments

Yes, absolutely. As a manufacturer, we have a professional engineering team. We can customize the dimensions, loading capacity (e.g., 60 tons, 80 tons), axle brand (FUWA/BPW), suspension type, and paint color to suit your specific road conditions and transport needs.

We use high-strength Q355 or T700 steel for the main beam. This ensures the trailer is lightweight yet strong enough to withstand heavy loads and rough road conditions in Africa and Central Asia.

Standard models usually take 15-20 working days after receiving the deposit. For urgent orders, we can even shorten it to 10 days. We will keep you updated with photos and videos during production.

Our standard term is T/T (30% deposit, 70% balance before shipping). For large orders, L/C (Letter of Credit) is also negotiable.

Yes, we provide a 24-month warranty for the main beam. For spare parts (like brake pads, lights), we supply original parts at factory cost for the lifetime of the trailer.

At Kales Vehicle, we understand that shipping costs are a major part of your investment. That’s why we offer multiple transport options tailored to your destination and budget.

Whether you choose Container Shipping for protection, Ro-Ro (Roll-on/Roll-off) for speed, or Bulk Cargo for cost savings, we ensure every trailer is handled with care. All vehicles undergo rigorous wax spraying and are covered with waterproof tarpaulins before shipment to prevent seawater corrosion during transit. We calculate the optimal stacking method (e.g., 3 units stacked together) to help you minimize freight costs.