Rugged & Durable

Built with high-strength steel and branded components to withstand tough road conditions

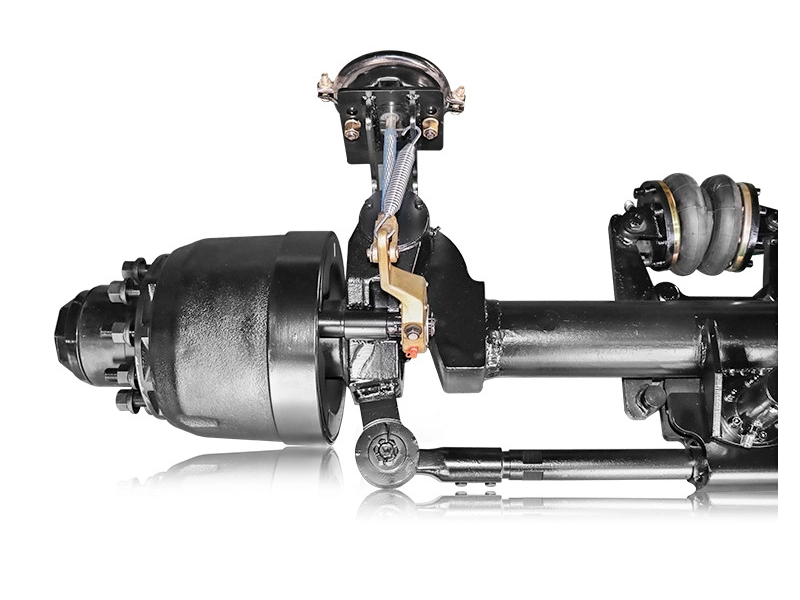

Kales Follower Steering Axles – Specialty Axles for Heavy Duty Applications

Revolutionize Your Fleet with Advanced Steering Technology

Improved Vehicle Handling

Reduced Turning Radius

Increased Vehicle Stability

Reduced Tire Wear

Lower Fuel Consumption

Perfect for Your Heavy-Duty Needs

The Kales Follower Steering Axles are specially designed for heavy-duty applications, aiming to completely transform your vehicle performance. Compared to traditional rigid axles, these specialty axles offer significant advantages, ensuring better handling, reduced wear, and improved efficiency.

Automatic Steering Angle Adjustment: The follower steering axles automatically adjust the steering angle of the wheels, making turns smoother and more flexible. This enhances driving control, especially in complex driving conditions.

Enhanced Maneuverability: By reducing the turning radius, these axles make vehicles more agile, particularly in narrow roads or complex terrains. This allows for easier navigation through tight intersections or curves, saving time during trips and loading/unloading operations.

Improved Stability During Turns: The follower steering axles enhance stability during turns, reducing the risk of rollovers and oversteer, thereby improving driving safety.

Less Heat Buildup on Tires: During turns, there is less heat buildup on the tires (as they roll rather than scrub against the road surface), which extends tire life and reduces the frequency of tire replacements.

Reduced Traction Resistance During Turns: Lower traction resistance during turns reduces tire drag, saving fuel. Over time, this can lead to significant fuel cost savings.

Whether you manage a fleet of trucks or operate in challenging environments, Kales Follower Steering Axles can provide you with exceptional performance and reliability.

Upgrade your fleet with Kales Follower Steering Axles and experience a comprehensive improvement in performance, efficiency, and safety. Contact us today to learn more about how these specialty axles can benefit your operations.

| Model | Max. Capacity(T) | Total Length(mm) | Wheel Track(mm) | Brake(mm) | Axle Tube(mm) | Studs(mm) | P.C.D(mm) | Hole Diameter(mm) |

Recommended Wheel

|

| KAFSAS11 | 11.5 | 2259 | 1950 | 420*180 | Φ127*16 | 10*M22*1.5 | 225 | 176 | 6.5-15

6.75*17.5 |

Noted:

1. The Trailer Axle track can be customized according to customer requirements

2. Axles can install ABS brake.

3. Axles can install Air brake chamber

0 comments

Yes, absolutely. As a manufacturer, we have a professional engineering team. We can customize the dimensions, loading capacity (e.g., 60 tons, 80 tons), axle brand (FUWA/BPW), suspension type, and paint color to suit your specific road conditions and transport needs.

We use high-strength Q355 or T700 steel for the main beam. This ensures the trailer is lightweight yet strong enough to withstand heavy loads and rough road conditions in Africa and Central Asia.

Standard models usually take 15-20 working days after receiving the deposit. For urgent orders, we can even shorten it to 10 days. We will keep you updated with photos and videos during production.

Our standard term is T/T (30% deposit, 70% balance before shipping). For large orders, L/C (Letter of Credit) is also negotiable.

Yes, we provide a 24-month warranty for the main beam. For spare parts (like brake pads, lights), we supply original parts at factory cost for the lifetime of the trailer.

At Kales Vehicle, we understand that shipping costs are a major part of your investment. That’s why we offer multiple transport options tailored to your destination and budget.

Whether you choose Container Shipping for protection, Ro-Ro (Roll-on/Roll-off) for speed, or Bulk Cargo for cost savings, we ensure every trailer is handled with care. All vehicles undergo rigorous wax spraying and are covered with waterproof tarpaulins before shipment to prevent seawater corrosion during transit. We calculate the optimal stacking method (e.g., 3 units stacked together) to help you minimize freight costs.