Rugged & Durable

Built with high-strength steel and branded components to withstand tough road conditions

in modern industrial logistics, efficient, eco-friendly, and cost-effective transportation has become key to enhancing business competitiveness. The Kales 58m³ 4-compartment powder tanker truck is specially designed to meet the bulk transport needs of dry powdered materials such as cement, fly ash, lime powder, mineral powder, and caustic soda pellets.

in modern industrial logistics, efficient, eco-friendly, and cost-effective transportation has become key to enhancing business competitiveness. The Kales 58m³ 4-compartment powder tanker truck is specially designed to meet the bulk transport needs of dry powdered materials such as cement, fly ash, lime powder, mineral powder, and caustic soda pellets.

It is an ideal transport equipment for industries like construction, energy, and chemical manufacturing.

Equipped with four independent compartments, this powder tanker can transport various types of powdered materials at the same time—such as cement and mineral powder, or lime powder and caustic soda pellets—without cross-contamination. This significantly improves vehicle utilization, transport efficiency, and reduces overall transportation costs.

The tank body is manufactured using high-strength wear-resistant steel, offering excellent corrosion resistance and durability. The frame structure uses T700 high-strength steel, providing strong torsional resistance, impact resistance, and collision protection, making it suitable for all kinds of complex road conditions.

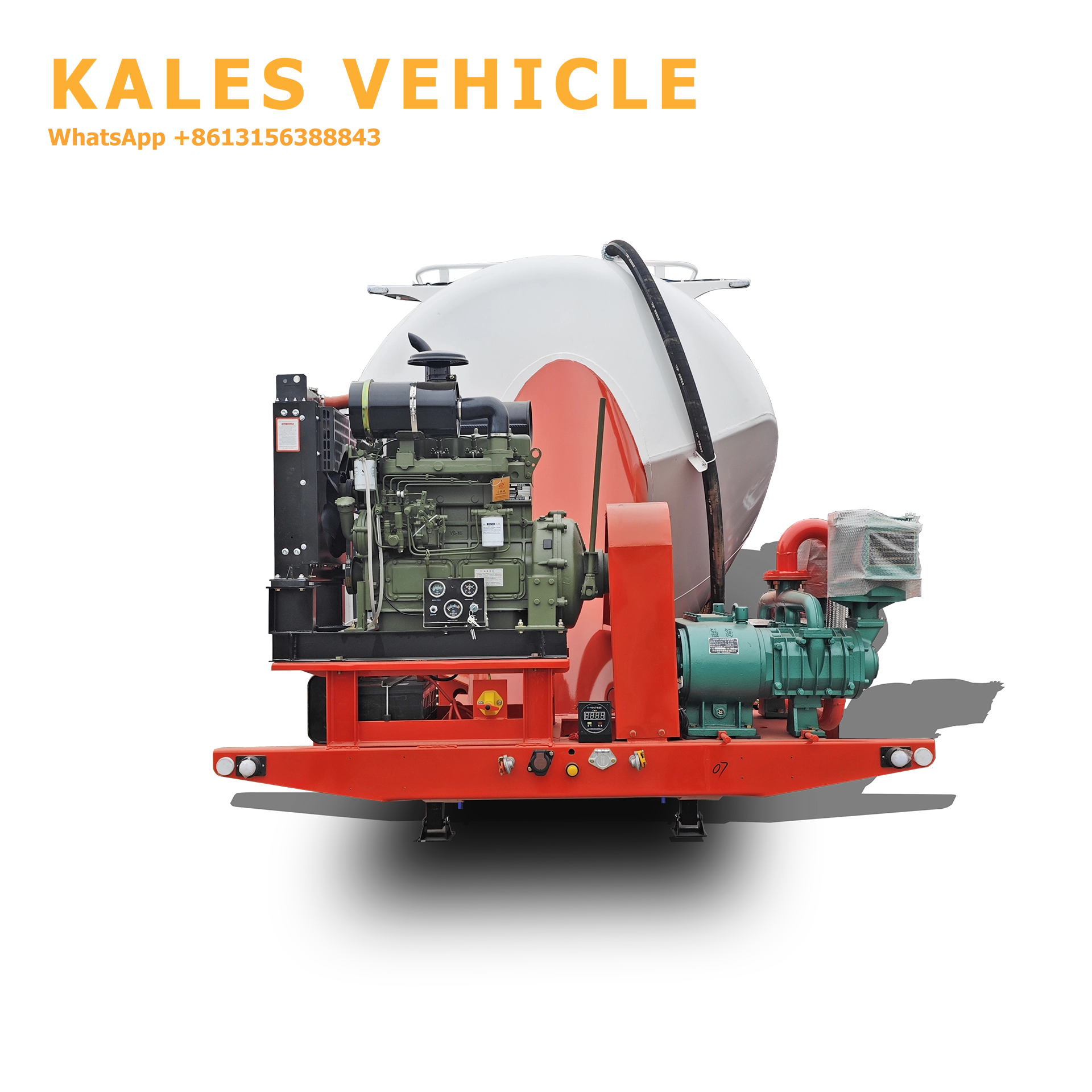

Integrated air compression system eliminates the need for external air sources, making loading and unloading more convenient and efficient.

All welds are completed using specialized welding equipment through a single-side double-sided forming process, ensuring smooth, uniform, and strong weld seams that completely prevent gas leakage and ensure fully sealed transportation.

Powered by a high-performance diesel air compressor unit driving the Bohai HYCW-12/2 air compressor (rated power: 38kW, air flow: 12m³/min), compressed air is delivered into the tank through pipelines. The fluidization device inside the tank increases the flowability of the powder material, allowing it to behave similarly to liquid, thus enabling smooth flow on the inclined fluidized bed.

During unloading, the pressure difference between the inside and outside of the tank allows the powder to be transported along the discharge pipeline to the designated location:

Horizontal conveying distance: up to 5 meters

Vertical conveying height: up to 15 meters

With the secondary blowing valve assisting in discharging, the unloading efficiency is further improved.

The piping system on the left side of the trailer is clearly arranged. The air compressor outlet pipe is connected to the inlet valves of the front and rear compartments of the tank, ensuring stable air supply.

The secondary assist-blowing valve is linked with the discharge pipe to further improve unloading speed and efficiency.

The Kales powder tanker adopts a fully enclosed tank structure, eliminating traditional paper packaging. Not only does this save a large amount of packaging materials, but it also significantly reduces manual handling effort and improves labor productivity. More importantly, the tank offers excellent sealing and moisture-proof performance, ensuring that materials like cement can be stored safely inside the tank for up to one year without degradation—truly achieving environmentally friendly and cost-effective transportation.

Ideal for:

Cement plants → Concrete batching plants

Mines → Smelting plants

Large infrastructure projects

Ports, railway engineering, and more

| Kales 58m³ 4-Compartment Bulk Powder Tanker trailer | ||

|---|---|---|

| Dimension | Size | |

| Length | 12500mm | |

| Width | 2550mm | |

| Height | 3900mm | |

| Weight | 11.8T | |

| Maximum carrying capacity | 50T | |

| Variety of transportation | Bulk cement | |

| Tank | Volume | 58m3 |

| Compartment | V-Shape | |

| Material | Carbon steel T700 high strength plate | |

| Thickness | 4mm | |

| Closure head | 5mm | |

| Roof pavement | Carbon steel Anti-skid net | |

| Vertical ladder | 1 welded at the rear with non-skid steps and foldable bottom. | |

| Manhole plate | External three-claw powder tank truck manhole cover | |

| Aircrew | 4120 Diesel engine | |

| 14 cubic meter single cylinder air compressor | ||

| Running mechanism | Axle | kales 13T |

| Leaf Spring | Factory Standard | |

| Tire | 1200R22.5 | |

| Rim | 9.0/Company standard 9.0 | |

| Landing gear | kales 28T Carbon Steel | |

| King pin | 90#/50# | |

| Accessories | Side defence | Carbon steel |

| Rear defence | Carbon steel | |

| Fender | Carbon steel | |

| Tool box | Company standard | |

| Spare tire rack | Company standard | |

| Extinguisher | Standard equipped | |

| Brake system | Air tank | Company standard Aluminum alloy |

| Brake chamber | double brake chamber | |

| Emergency valve | WABCO | |

| Electric system | Wire harness | 7 Wire |

Advanced Technology – Core components from well-known domestic and international brands ensure stable and reliable operation.

Smart & Efficient – Dual system of fluidization + assist blowing enhances unloading speed and efficiency.

Flexible Transport – 4-compartment design meets diverse transport needs.

Durable & Safe – High-strength steel and military-grade welding withstand harsh environments.

Eco-Friendly & Energy-Saving – Reduces packaging waste and prevents moisture damage, supporting green logistics.

Kales 58m³ 4-compartment powder tanker – Make your powdered material transport more efficient, economical, and eco-friendly!

📞 Contact us for detailed specifications and quotations

🌐 Website: www.kalestruck.com

📱 WhatsApp: +86 131 5638 8843

Let Kales be your trusted partner and build a future-oriented efficient logistics ecosystem together!

0 comments

Yes, absolutely. As a manufacturer, we have a professional engineering team. We can customize the dimensions, loading capacity (e.g., 60 tons, 80 tons), axle brand (FUWA/BPW), suspension type, and paint color to suit your specific road conditions and transport needs.

We use high-strength Q355 or T700 steel for the main beam. This ensures the trailer is lightweight yet strong enough to withstand heavy loads and rough road conditions in Africa and Central Asia.

Standard models usually take 15-20 working days after receiving the deposit. For urgent orders, we can even shorten it to 10 days. We will keep you updated with photos and videos during production.

Our standard term is T/T (30% deposit, 70% balance before shipping). For large orders, L/C (Letter of Credit) is also negotiable.

Yes, we provide a 24-month warranty for the main beam. For spare parts (like brake pads, lights), we supply original parts at factory cost for the lifetime of the trailer.

At Kales Vehicle, we understand that shipping costs are a major part of your investment. That’s why we offer multiple transport options tailored to your destination and budget.

Whether you choose Container Shipping for protection, Ro-Ro (Roll-on/Roll-off) for speed, or Bulk Cargo for cost savings, we ensure every trailer is handled with care. All vehicles undergo rigorous wax spraying and are covered with waterproof tarpaulins before shipment to prevent seawater corrosion during transit. We calculate the optimal stacking method (e.g., 3 units stacked together) to help you minimize freight costs.