New vs. Retread: How to Slash Semi-Trailer Tire Costs by 50%

In the world of fleet management, tires are typically the second-largest operating expense after fuel. With a standard semi-trailer requiring 8 to 12 tires, keeping them in prime condition is vital for safety and efficiency. However, constantly purchasing premium brand new tires can drain your budget quickly.

Is there a smarter alternative? Enter Tire Retreading—a sustainable strategy that is transforming how logistics companies manage their Cost Per Mile (CPM). This guide explores how retreading works, its safety reliability, and the massive savings it offers for heavy-duty fleets.

What is Tire Retreading? (Understanding the Process)

Tire retreading (often called “recapping” or “remolding”) is the process of giving a fresh lease on life to a worn tire.

It is based on a simple engineering fact: The tire casing (the internal structure) is built to last much longer than the tread (the outer rubber).

Here is how the professional retreading process works:

- Inspection: The tire undergoes a rigorous examination using non-destructive testing and laser inspections. Only casings with zero structural damage qualify.

- Buffing: The old, worn tread is shaved off to prepare a clean, uniform surface.

- Application: A new, high-quality rubber tread is applied to the casing.

- Vulcanization: The tire is heated under pressure to bond the new tread to the original casing permanently.

The result? A tire that performs like new but utilizes the existing, durable structure you already own.

Safety Myth-Busting: Are Retreads as Safe as New Tires?

A common misconception is that retreaded tires are less safe or prone to peeling (the infamous “road alligator” myth). The reality is that truck tire casings are engineered to withstand multiple life cycles.

- Lifespan: Quality retreads typically deliver 60-80% of the mileage of a brand-new tire.

- Durability: Reputable manufacturers use specialized rubber compounds that allow some retreads to match—or even exceed—the lifespan of budget-tier new tires.

- Reliability: Major airlines and school bus fleets use retreaded tires daily, proving their safety standards.

Fact Check:

For semi-trailers, which bear static loads rather than steering torque, retreads are an exceptionally safe and logical choice approved by industry standards.

The ROI Analysis: How Much Can Fleets Save?

Implementing a tire retread program is the fastest way to lower your fleet’s maintenance costs. Let’s break down the math.

The 30-50% Rule

Generally, manufacturing a retread requires 7 gallons of oil, compared to 22 gallons for a new tire. This efficiency translates directly to price: retreads cost 30% to 50% less than comparable new tires.

A Practical Calculation:

- Average New Tire Cost: ~$400

- Cost to Replace 8 Trailer Tires: ~$3,200

- Potential Savings with Retreads: By choosing retreads, you could save between $960 and $1,600 per trailer per replacement cycle.

If your fleet utilizes specialty or high-end tires (e.g., for heavy hauling or off-road mining), the savings double. For a fleet of 50 trailers, this strategy could save tens of thousands of dollars annually.

Conclusion: Maximizing Fleet Uptime

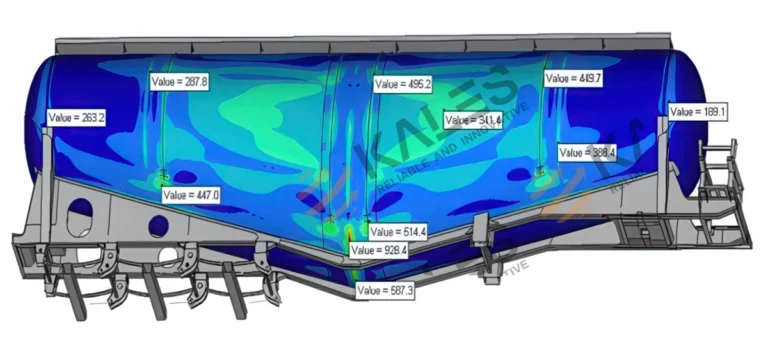

Heavy hauling relies on reliable equipment. Without good tires, even the best Kales semi-trailer cannot run efficiently.

Retreading is not just about being “cheap”—it is about being economically efficient. By combining high-quality new tires for your steer axles with a robust retreading program for your trailer axles, you can maximize uptime, reduce environmental impact, and significantly lower your operating costs.

Pro Tip for Kales Customers:

The key to successful retreading is starting with a high-quality tire casing. When you buy a new Kales Trailer, ensure you maintain proper tire pressure to protect the casing for future retreading.