Running a profitable logistics fleet means constantly battling rising diesel prices. While standard maintenance—like ensuring proper tire pressure—is essential, it is often not enough to protect your margins.

To truly maximize efficiency, you need to address the invisible enemy: Aerodynamic Drag.

Quick Answer: The most effective aerodynamic devices for semi-trailers include side skirts (1-5% savings), boat tails (1-5% savings), nose cones (1-2% savings), and vented mud flaps. Combining these technologies on your Kales semi-trailers can result in total fuel savings of over 10%.

1. Aerodynamic Side Skirts (The Industry Standard)

Figure 1: Kales Curtain Sider equipped with side skirts to smooth undercarriage airflow.

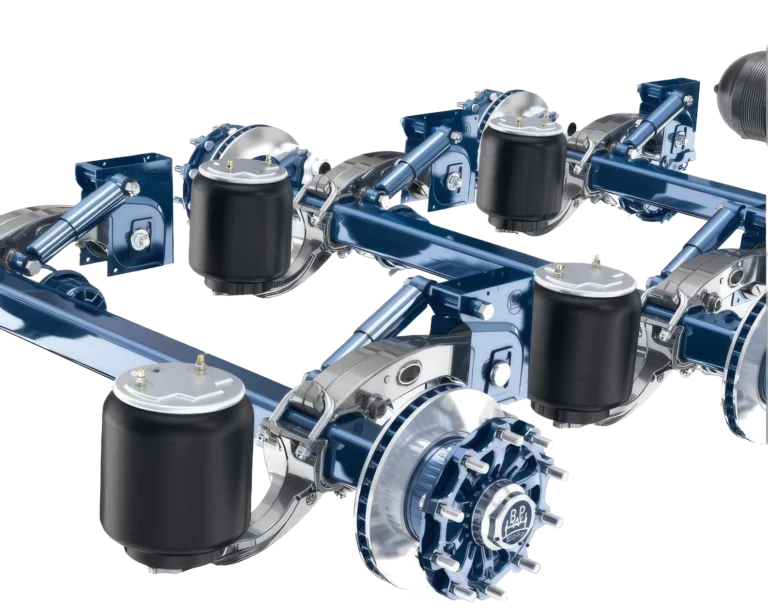

Trailer side skirts are panels that hang on both sides of the chassis. Their primary function is to prevent wind from rushing underneath the trailer, where it hits the crossmembers and axles, creating massive turbulence.

According to the NACFE, side skirts are the industry’s most widely adopted drag-reducing device. They are particularly effective on Curtain Side Trailers and box vans.

- How it works: Channels air along the smooth sides of the trailer rather than into the complex undercarriage.

- Proven Savings: Typically provides fuel savings of 1% to 5% compared to standard trailers.

2. Trailer Boat Tails (Rear Fairings)

Figure 2: Boat Tails reduce the low-pressure suction zone at the rear.

The rear of a square trailer, such as a Dry Van, creates a low-pressure vacuum zone (often called “suction drag”) that literally pulls the vehicle backward. “Boat Tails” taper the airflow at the rear to solve this physics problem.

- How it works: Directs airflow inward at the rear to minimize drag.

- Proven Savings: High-quality systems can offer potential fuel savings ranging from 1% to 5%.

3. Nose Cones & Gap Fairings

Figure 3: Gap Fairings bridge the space between the tractor and trailer.

The open space between the truck cab (tractor) and the trailer face is an aerodynamic nightmare. Air gets trapped here, hitting the flat front of the trailer and acting like a brake.

Installing a Nose Cone creates a “bridge” for the air to flow smoothly from the truck cab over the trailer roof.

- How it works: Prevents air from slamming into the trailer’s “headboard”.

- Proven Savings: Typical fuel consumption reduction of 1% to 2%.

4. Aerodynamic Wheel Covers

Often overlooked, the rotating wheels of a semi-trailer create a significant amount of “churning” turbulence.

Aerodynamic Wheel Covers (or Hubcaps) fit over the steel or aluminum rims to create a flat, smooth surface. This prevents air from getting trapped inside the deep dish of the wheel rim.

- How it works: Smoothens the airflow passing specifically over the trailer axles.

- Proven Savings: A cost-effective upgrade that can yield 1% to 2% in savings.

5. Vented Aerodynamic Mud Flaps

Figure 4: Vented mud flaps allow air to pass through, reducing drag.

Traditional solid mud flaps protect vehicles from debris, but their flat, rectangular design acts like a parachute, trapping wind and increasing drag.

Vented Fenders solve this by allowing air to pass through the slats while still effectively catching water and road spray.

- Proven Savings: Can improve fuel economy by approximately 0.5% to 1%.

Summary: Fuel Savings ROI

| Device | Function | Savings |

| Side Skirts | Under-trailer flow | 1% – 5% |

| Boat Tails | Rear suction reduction | 1% – 5% |

| Nose Cones | Cab-Trailer gap | 1% – 2% |

| Wheel Covers | Wheel turbulence | 1% – 2% |

Maximize Your Profit Today

Combining these technologies can yield cumulative fuel savings of over 10%.

Looking to upgrade your fleet? Kales Vehicle offers factory-installed aerodynamic packages.