Common Questions from Fleet Managers:

“My tank trailer has EBS; does that mean it brakes automatically?”

“Is standard ABS enough? Why do I need RSS (Roll Stability)?”

“Does the trailer need to support AEBS, or is that just for the tractor truck?”

If you think a semi-trailer is just a “passive metal box” being dragged behind a truck, think again.

In modern intelligent transport systems, the trailer’s own safety systems—especially the braking architecture—directly determine whether the entire combination can stop safely, stay stable, or actively avoid accidents in critical moments. As a professional semi-trailer manufacturer, Kales Vehicle is here to walk you through ABS, EBS, RSS, and AEBS, clarifying their relationships, capabilities, and common misconceptions.

1. The Foundation: ABS — Anti-Lock, Steering Control

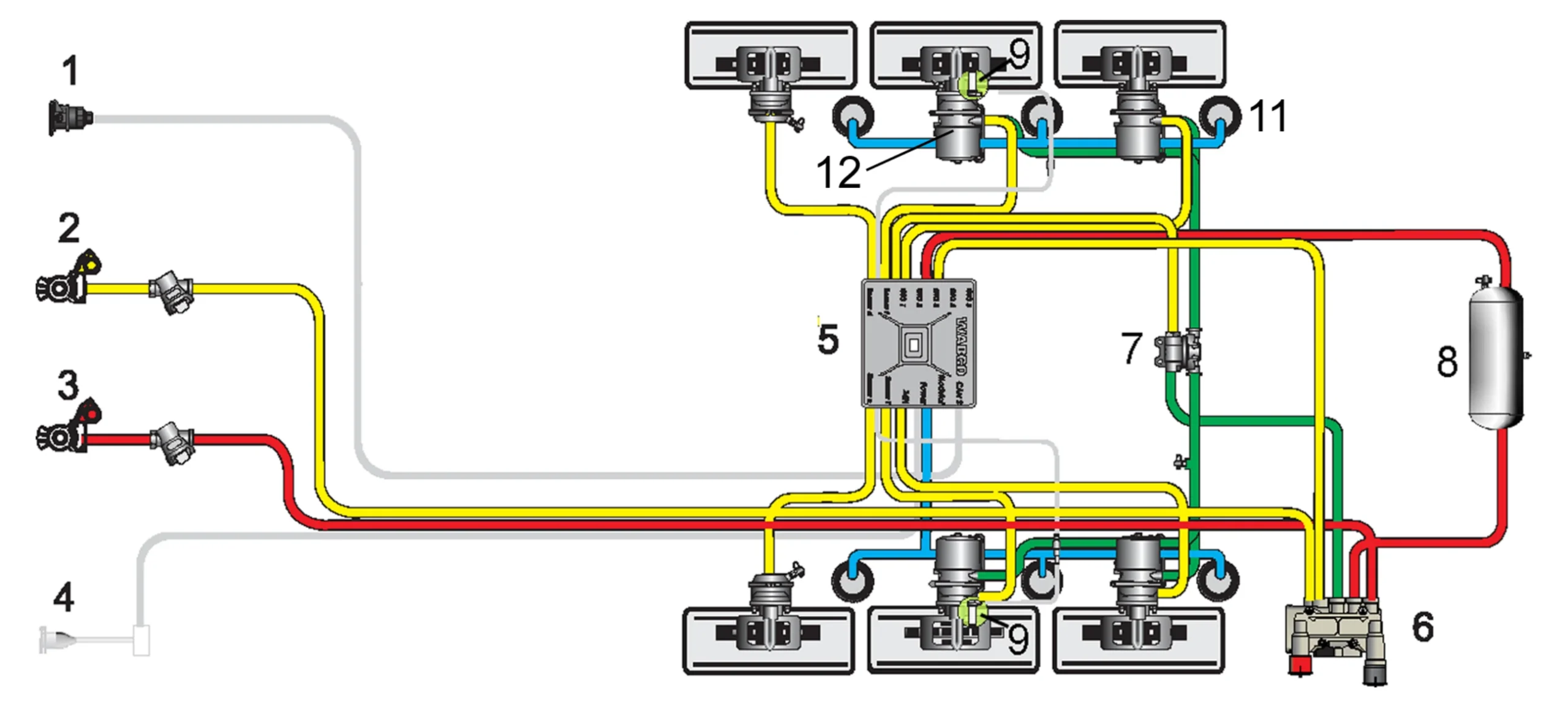

ABS (Anti-lock Braking System) is currently the mandatory standard for trailers in many regions. Fundamentally, it is an extension of the pneumatic braking system that allows for electronic intervention.

Core Function:During emergency braking, ABS monitors wheel speed to prevent trailer wheels from locking up. Once a wheel locks, the tire loses lateral grip, causing the trailer to slide, swing, or even lead to a catastrophic Jackknife accident.

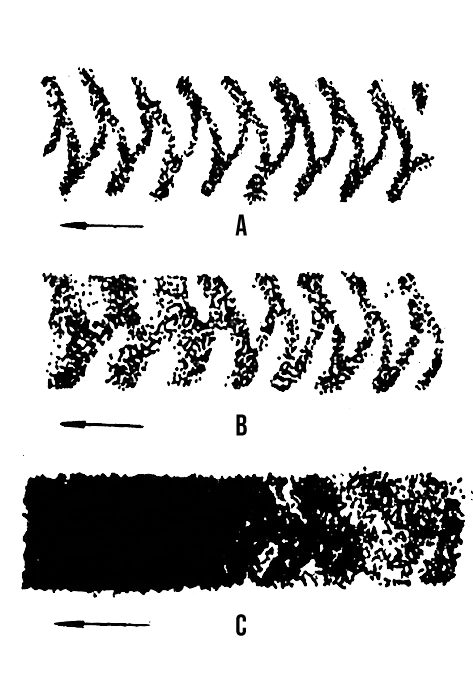

The image on the right visually compares tire marks under three conditions:

- Rolling: Clear tread pattern, reliable steering control.

- ABS Active: Dotted/intermittent marks, “brake-and-roll”, directional control maintained.

- Locked-up: Solid dark skid marks, total loss of control.

Fig 1: Tire Mark Comparison: A. Rolling vs B. ABS Active vs C. Locked Wheel

Principle & Advantages:

The driver’s braking action is transmitted pneumatically via the foot valve. Wheel speed sensors are installed on key axles (typically 2S/2M or 4S/2M configurations). When the system detects an impending lock-up, the modulator valve rapidly adjusts air pressure, achieving a “rapid pulsing” effect several times per second.

- Simple Control Principle: Adds electronic monitoring to traditional air lines. Low cost and easy maintenance.

- Foundation for Expansion: This logic forms the hardware platform for advanced functions like ESP (Electronic Stability Program).

Fig 2: Typical Semi-Trailer 2S/2M ABS System Schematic1. ISO 7638 Power Supply 2. Service Line 3. Supply Line 4. Stop Light Power (ISO 1185, Optional) 5. TEBS Modulator (with pressure sensors) 6. Park Release Emergency Valve (PREV) 7. Overflow Valve 8. Service Brake Reservoir 9. ABS Speed Sensor 11. Suspension Air Bag 12. Spring Brake Chamber. (Lines represent cable and pipe connections)

2. Advanced Guardian: Rollover Prevention (RSS/RSP/RSC)

In the realm of “Intelligent Trailers,” the anti-rollover system is the true game-changer. Although manufacturers use different names, the core objective is identical:

- RSS (Roll Stability Support) —— ZF / WABCO

- RSP (Roll Stability Program) —— Knorr-Bremse

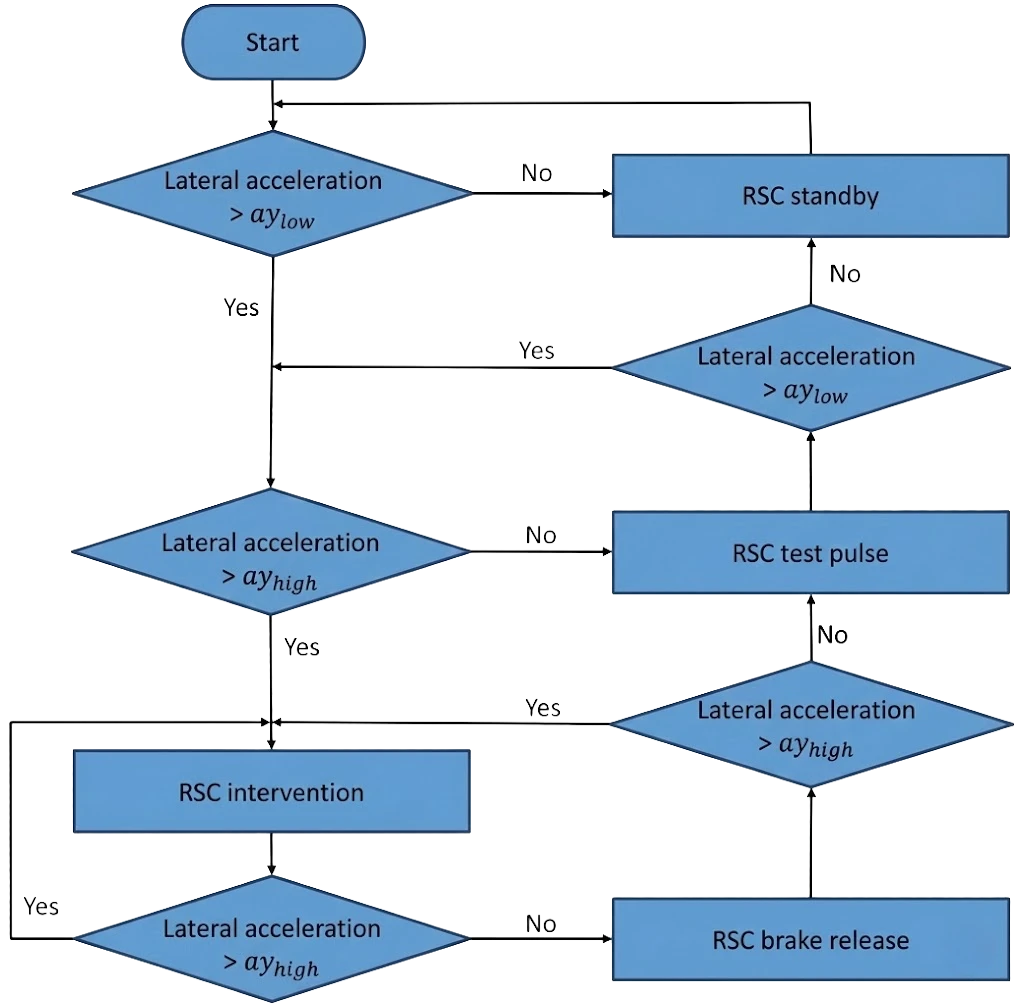

- RSC (Roll Stability Control) —— Haldex

1. Why do trailers roll over?

According to the ECE R111 standard, a rollover becomes a critical risk when lateral acceleration reaches approximately 0.4G. For trailers carrying liquids, hanging meat, or unevenly distributed loads, this threshold is even lower.

Fig 3: RSS Logic: The system actively applies brakes to specific wheels to counteract rollover forces.

2. How does it react faster than a human?

This system relies on physics and algorithms, not driver reaction time. Here are the two mainstream working logics:

🔵 WABCO RSS 3-Stage Logic

- Stage 1 (Warning @ ~0.2G): Applies light braking (approx. 2 bar). Purpose: Test wheel grip and pre-charge the system, not to decelerate.

- Stage 2 (Strong Intervention @ ~0.3G): If lateral force increases, the system brakes hard to forcibly reduce speed.

- Stage 3 (Correction): Applies higher brake pressure to the inner wheels of the curve to prevent the trailer from straightening out abruptly, guiding it through the turn.

🟠 Knorr RSP Smart Logic

Test Pulse: When rollover risk is detected, the system sends a tiny brake signal to check if the “inner wheels” slow down.

If they slow down, they have grip. If they do NOT slow down, it means the wheels are about to lift off (slip), and the system immediately identifies high risk and applies full braking.

3. A Warning for Fleets and Drivers

🚨 System Activation = Near Miss Event

If the driver feels the trailer “tugging” back, or the telematics system reports an RSS activation, take it seriously:

- Without this system, the vehicle might have already rolled over.

- It is a severe warning regarding driving behavior (cornering too fast) or load distribution (CG too high).

- Mandatory Check: Frequent activation increases wear. Always check brake linings and suspension systems.

3. EBS: Making Braking “Fast, Precise, and Stable”

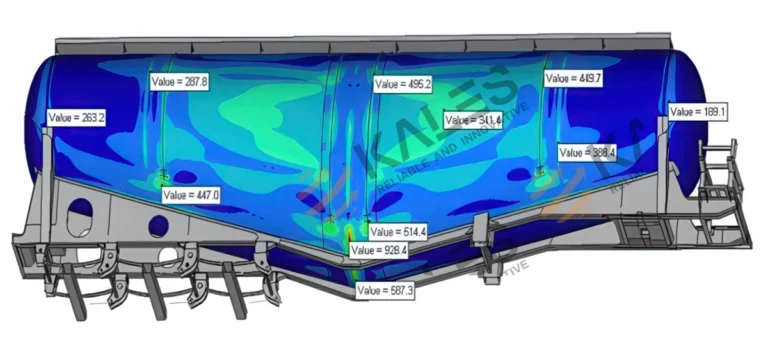

EBS (Electronic Braking System), also known as Brake-by-Wire, is not a single function but a powerful electronic control platform. It integrates sensors and actuators, often deeply linked with the air suspension.

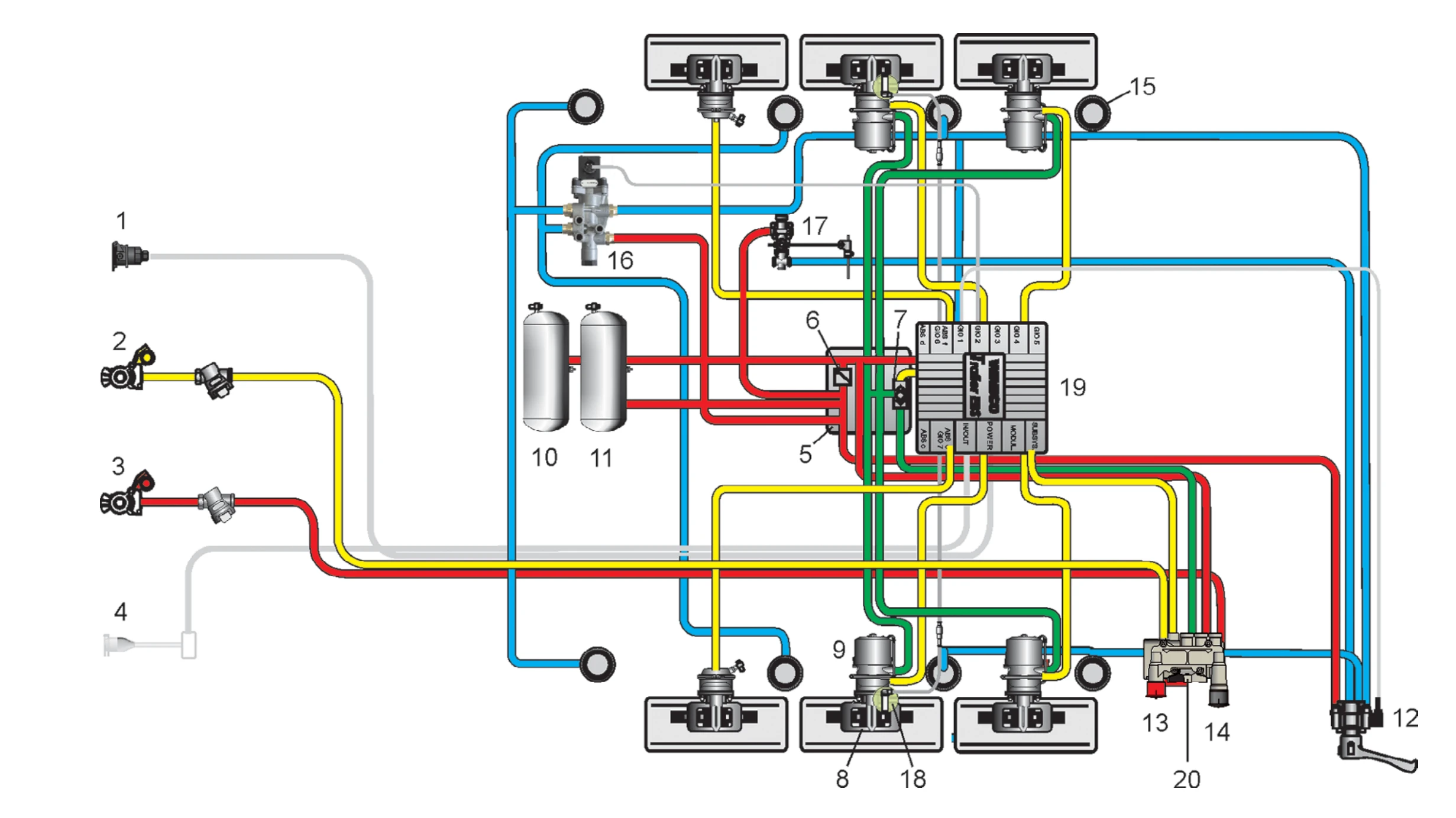

Fig 4: EBS Braking System Schematic Integrated with Air Suspension1. ISO 7638 Power Supply 2. Service Line 3. Supply Line 4. Stop Light Power (Optional) 5. Pneumatic Extension Module (PEM) 6. Overflow Valve (Integrated) 7. Charging Valve (Integrated) 8. Service Brake Part 9. Spring Brake Chamber 10. Service Reservoir 11. Air Suspension Reservoir 12. Raise/Lower Valve 13. Red Button (Park) 14. Black Button (Release) 15. Air Bag 16. Lift Axle Valve 17. Levelling Valve 18. ABS Sensor 19. TEBS Modulator 20. PREV.

1. How it works: From “Blowing Air” to “Digital Signals”

Traditional air brakes rely on the foot pedal to control air flow physically. EBS uses a pedal position sensor to detect the driver’s braking intent. The control unit calculates the required brake pressure for each axle based on speed, load, and wheel speed.

This information is transmitted via the CAN Bus to the Electro-Pneumatic Modulator (EPM), which adjusts pressure directly near the wheels. This eliminates the delay caused by long pneumatic lines.

2. Hidden Benefits of Modern EBS

Modern EBS (like systems used by Kales Vehicle) typically uses a modular design, integrating the ECU, sensors, and pneumatic control into one compact component, simplifying the trailer chassis layout.

🔍 The “Invisible Bonuses” of EBS: Not just fast, but smart

- Coupling Force Control (CFC): The system optimizes the braking timing and force between the tractor and trailer, preventing “trailer push” or “tugging,” making the combination drive more smoothly.

- Brake Blending: Intelligently distributes deceleration intent between endurance braking (like retarders) and service braking (pads), extending brake pad life.

- Lining Wear Control: Automatically adjusts braking force distribution across axles to ensure even wear on all brake pads, simplifying fleet maintenance.

- Multi-Function Integration: Modern EBS modules often integrate Lift Axle Control (LAC), RSS, dynamic wheelbase control, TPMS, and overflow valves, eliminating the need for complex external plumbing.

Comparison Summary:

| Feature | Traditional ABS (Pneumatic) | Smart EBS (Electronic) |

|---|---|---|

| Signal Transmission | Air Pipes (Slow) | CAN Bus Signal (Light Speed) |

| Response Delay | 0.3 ~ 0.6 Seconds | Almost Zero Delay |

| Functionality | Anti-lock Only | Lift Axle, Wear Balance, Coupling Control |

4. AEBS Synergy: The Danger of “Lag”

Although AEBS (Advanced Emergency Braking System) decisions are made by the tractor’s radar and camera, the trailer’s execution capability is critical.

- ❌ Trailer with Standard ABS only:

When the tractor triggers a violent AEBS stop, the trailer reacts with a pneumatic lag. The massive inertia of the trailer pushes the tractor forward. This extends braking distance and causes a dangerous “Pushing Effect,” potentially leading to loss of control. - ✅ Trailer with EBS:

As the tractor brakes, the trailer receives the signal via the ISO 11992 interface (or ISO 7638) instantly. It applies full braking force with zero delay, creating a “Stretching Effect” that keeps the entire vehicle combination straight and stable.

5. The Pyramid of Trailer Intelligent Braking

[Visual: Imagine a Pyramid Structure]

Fig 5: Hierarchy of Intelligent Safety Technology

Legal Baseline

Electronic Brain

Active Safety

6. Advice for Fleet Managers and Buyers

As a professional trailer manufacturer, Kales Vehicle suggests considering the following:

1. Think Long Term: Choose EBS/RSS

If you transport liquids (tank trailers), livestock, or high-value cargo, we strongly recommend EBS with RSS. While the initial cost is higher, preventing just one rollover accident covers the cost many times over.

2. Don’t Ignore the “ISO 7638” Cable

A Fatal Blind Spot for Drivers! The trailer’s ABS/EBS system MUST be powered and communicate via the ISO 7638 Coiled Cable (the thickest plug).

If unplugged or damaged, the most advanced EBS becomes “brain dead,” reverting to an old-school air brake with NO anti-lock or anti-rollover protection. Always check before driving.

ISO 7638 Connection

3. Tractor-Trailer Compatibility

When buying, check if the spec sheet confirms “EBS Supported” and “RSS/RSP Functionality.” Even if your tractor truck is state-of-the-art, an outdated trailer braking system will compromise the safety of the entire rig.

Conclusion: Safety is the Biggest ROI

In the era of intelligent transport, the trailer is no longer a silent partner. Don’t just look at volume and price; ask: “Is the braking system smart enough?”

Kales Vehicle is dedicated to providing the safest, most durable semi-trailer solutions for global clients.