From GB to ASTM Standards: Building a Defense Line for Safety, Cost-Reduction, and Compliance

Based on the latest GB/T 1591-2018 standards and real-world failure analysis, this guide provides a complete technical framework for international fleet managers to procure high-quality semi-trailers from China.

📖 Technical Index

- 1. Industry Evolution: High-Tensile Steel

- 2. Steel Selection Radar: Key KPIs

- 3. Risk Mitigation: 5 Major Failures

- 4. Aluminum & Stainless Steel Specs

- 5. Non-Metal: Flooring & Composites

- 6. Joints: Welding, Huck Bolts & Sealants

- 7. Global Standards (GB/ASTM/EN)

- 8. ROI Analysis: Total Cost of Ownership

I. Introduction: Material Breakthroughs in Manufacturing

Selecting the right semi-trailer is a system engineering challenge that combines mechanics, metallurgy, and economics. The manufacturing sector is undergoing a profound transformation:

- Steel Upgrades: A complete transition from older Q345 to Q355 High-Strength Low-Alloy (HSLA) steel; Q700 (700MPa) is standard for lightweighting, while BST1500 dominates the wear-resistant sector.

- Material Diversification: Aluminum alloy extends beyond tankers to fuel and food-grade transport; Stainless steel expands to corrosive solid transport.

- Globalization: Designs are now strictly benchmarked against ASTM (USA) and EN (Europe) standards for export compliance.

II. Core Material Systems: The Chassis Foundation

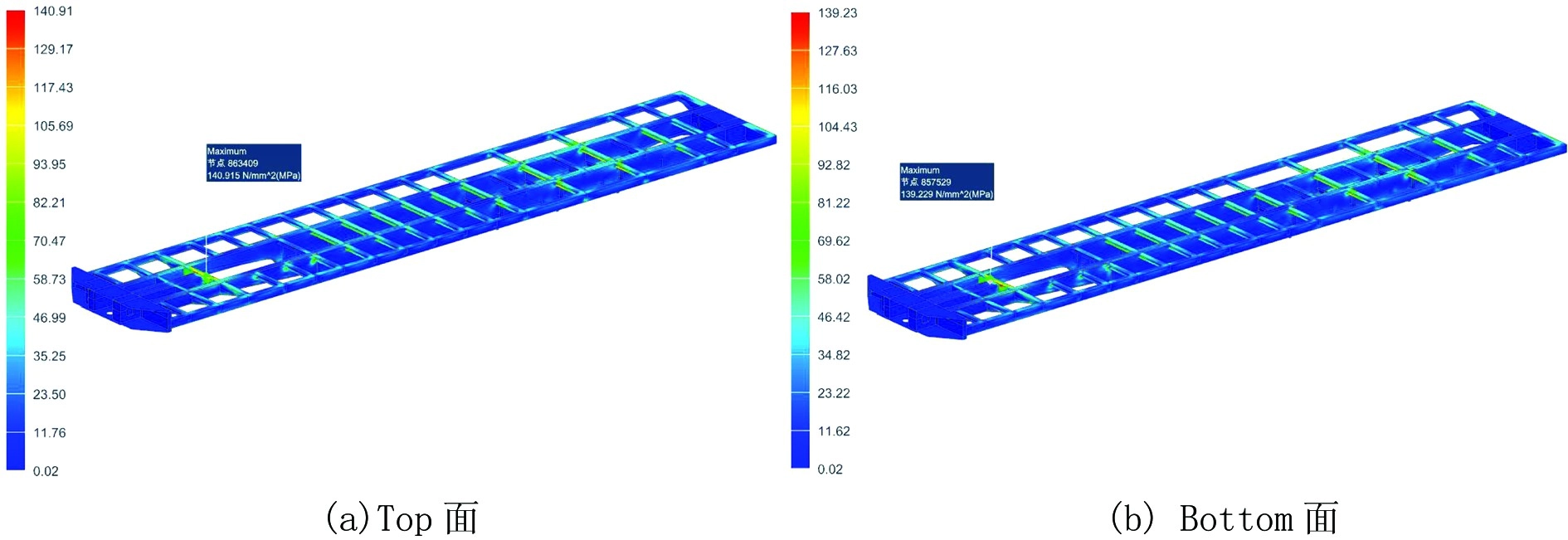

Diagram of Semi-Trailer Chassis Structure (Finite Element Analysis Stress Map)

1. Steel: The Backbone of Your Trailer

| Category | Grade | Application & Notes |

|---|---|---|

| Mild Carbon Steel | Q235B (ASTM A36) | Toolboxes, Mudguards. Lowest cost, strictly prohibited for main load-bearing structures. |

| HSLA Steel | Q355B/C/D/E | Main Beams, Cross Members. The industry standard, replacing Q345. Equivalent to S355JR or A572 Gr.50. |

| High-Tensile Steel | Q700L/E (T700) | Lightweight Main Beams (15-30% weight reduction). Superior tensile strength. |

| Wear-Resistant Steel | BST1500 / NM450 | Dump Trailer floors. Hardox equivalent. BST1500 offers ≥1500MPa tensile strength. |

III. Key Technical Indicators for Steel Selection

The Selection Mantra: “L for Forming, X for Welding; E for Cold Climates, Preheat for 1500.”

| Grade | Yield Strength | Carbon Equiv. (CEV) | Impact Energy (-40℃) | Best Use Case |

|---|---|---|---|---|

| Q355E | ≥355 MPa | ≤0.42 | ≥34 J | Mining & Off-Road. High toughness. |

| Q700E | ≥700 MPa | ≤0.50 | ≥34 J | Cold Climates (Russia/Canada). |

| BST1500 | ≥1300 MPa | >0.60 | Available @ -20℃ | Extreme Wear Resistance. |

IV. 5 Major Failure Risks & Prevention Strategies

Based on real-world failure analysis cases.

🔴 Risk 1: Cold Brittleness (Brittle Fracture)

Case Study: A dump trailer using standard BST700L (no impact rating) suffered a main beam fracture at -32°C. Tests revealed impact energy of only 8J (Safe threshold ≥27J).

Prevention:

- Grade Selection: For cold regions, strictly specify Q355E or Q700E.

- Contract Clauses: Mandate “Charpy V-Notch Impact Energy ≥27J @ -40°C”.

🔴 Risk 2: Welding Cold Cracks

Microscopic comparison of Healthy Weld vs. Cold Crack in High Tensile Steel

Root Cause: High tensile steels have high carbon equivalents, leading to hydrogen-induced cracking.

Prevention:

- Pre-heating: Q700 requires 150–200°C; BST1500 requires 200–250°C.

- Post-Weld Heat Treatment: Essential for releasing hydrogen.

- Inspection: 100% MT/UT testing is non-negotiable.

🔴 Risk 3: Structural Buckling (Over-Lightweighting)

Symptom: Chassis distortion on rough roads; “Wavy” buckling of the web plate.

Prevention:

- Minimum Thickness: Web plate thickness should never go below 5mm, even when using Q700.

- Design Check: FEA Verification must show first-order modal frequency ≥8 Hz and a safety factor ≥2.0.

- Avoid: Do not blindly replace 6mm Q355 with 4mm Q700.

🔴 Risk 4: Corrosion & Rust

Prevention:

- Surface Prep: Mandatory Sa2.5 Sandblasting (Roughness Rz=40–70 μm).

- Coating System: Epoxy Zinc-Rich Primer (≥60μm) + Polyurethane Topcoat.

- Coastal Areas: Use Polyurea chassis armor.

🔴 Risk 5: Counterfeit Materials

Case: A factory used “HQ700” which turned out to be Q420. The chassis bent within 6 months.

Prevention:

- Source: Buy only from mills with IATF 16949 certification (e.g., Baosteel, Ansteel).

- Verification: Request the original MTC (Mill Test Certificate) and cross-check Heat Numbers.

- On-Site Test: Perform spectral component analysis + tensile testing upon material arrival.

V. Aluminum & Stainless Steel: Applications

1. Aluminum Alloy (5083/6061)

- Applications: Tanker bodies (5083-H116), Aviation Fuel (Non-sparking).

- ⚠️ Galvanic Corrosion: Aluminum and Steel create a battery effect. Solution: Use Rubber/PTFE isolation gaskets; never bolt directly metal-to-metal.

- ⚠️ Fatigue: Promote Friction Stir Welding (FSW) for 90% joint strength retention.

2. Stainless Steel (304/316L)

- Applications: Chemical tankers (316L for acid resistance).

- ⚠️ Intergranular Corrosion: Always choose Low-Carbon grades (304L/316L).

- ⚠️ Pickling: Post-weld acid washing (passivation) is mandatory.

VI. Non-Metal Components: Flooring

1. Composite Materials (FRP/GRP)

Top choice for Reefer Trailers. No thermal bridging.

- Selection Key: The Gel Coat must be UV-Resistant to prevent yellowing. Glass fiber content should be ≥25%.

2. Flooring Materials

| Container Grade Bamboo | China’s Competitive Edge. High strength, water-resistant, and more durable than plywood. Standard thickness: 28-30mm. |

| Hardwood (Apitong) | The standard for US/European markets. Extreme nail-holding power for securing heavy machinery. |

VII. Joint Technology: Welding vs. Mechanical

Structural integrity depends 30% on material and 70% on connection technology.

1. Welding Process

| Material | Consumables (AWS) | Critical Process |

|---|---|---|

| HSLA (Q355) | ER70S-6 | Standard MAG welding. |

| High-Tensile (Q700) | ER70-G | Must Preheat 100-150℃! |

| Wear-Resistant | ER50-6 (Base) + ER70-G | Preheat 200℃ + Soft wire base layer. |

| Aluminum (5083) | ER5356 / ER5183 | Indoor welding only (Wind protection). |

| Stainless (304) | ER308L | Must be Pickled & Passivated. |

2. Mechanical Fastening: The Huck Bolt

✅ The Solution for Steel-Aluminum Joints

- Why: Steel and Aluminum cannot be welded together due to different melting points.

- Benefit: Vibration resistance is 5x that of standard nuts/bolts. Permanent locking.

- Anti-Corrosion: Must use Dacromet coated collars.

3. Sealing Process (Waterproofing)

The final defense for keeping cargo dry.

- ❌ Acidic Silicone: Cheap but releases acetic acid, corroding metal and peeling paint.

- ✅ MS Polymer Sealant: The industry standard. Solvent-free, UV resistant (10+ years), and paintable.

VIII. Global Standards Comparison Table

| China GB | Europe EN | USA ASTM | Note |

|---|---|---|---|

| Q235B | S235JR | A36 | Mild Steel |

| Q355B | S355JR | A572 Gr.50 | HSLA Steel |

| Q700 | S700MC | A514 Gr.B | High Tensile |

| 5083-H116 | EN AW-5083 | AA 5083 | Marine Alum. |

IX. Total Cost of Ownership (TCO) & Recommendations

💡 ROI Case Study

An Aluminum Alloy Box Trailer is 2.2 tons lighter than a steel one. Based on 100,000 km/year, this weight saving translates to significant fuel savings or additional payload revenue. The Payback Period is typically under 6 months.

| Operational Scenario | Chassis Material | Body Material | Tech Requirement |

|---|---|---|---|

| General Cargo | Q355B | Corrugated Steel | Standard Painting |

| Long-Haul Logistics | Q700E | 5083 Aluminum | Huck Bolt Connections |

| Fuel/Hazardous | Q550 | 5083 Aluminum | Anti-static, Air-tightness |

| Mining/Off-Road | Q700E | BST1500 (Hardox) | Pre-heat weld, Chassis Armor |

Conclusion: The “Safety-Longevity-ROI” Trinity

Modern semi-trailer sourcing is no longer just about price. Q355 offers the best baseline value, Q700 dominates lightweighting, and Aluminum is essential for specialized ROI. Our Advice: Don’t just buy “Steel”—buy the right steel for your specific terrain.