🚛 Applications: Expertly designed for dry bulk powders (particle size ≤ 0.1mm) including bulk cement, fly ash, lime, mineral powder, and flour.

🌍 About Kales Vehicle: A Premier Powder Tanker Manufacturer

Founded in 2012 and headquartered in Shandong, China, Kales Vehicle has over a decade of specialized experience in semi-trailer R&D and manufacturing. We have delivered 12,000+ units globally, including over 2,000 pneumatic dry bulk trailers, serving heavy industry clients across East Asia, Southeast Asia, Central Asia, the Middle East, and Africa.

We don’t settle for “good enough.” We build heavy-duty transport equipment engineered to withstand the toughest job site conditions.

❓ Why High-Quality Cement Bulkers Are Difficult to Perfect

A common misconception is that a powder tanker is simply “a steel tank welded onto a chassis.”

In reality, achieving fast discharge speeds, minimal residue rates, stable handling, and long-term chassis durability depends entirely on precision engineering. A poorly built tanker leads to clogged pipes, structural cracks, and profit loss.

Follow us as we walk you through the 7-step manufacturing journey of a Kales bulk powder transport trailer.

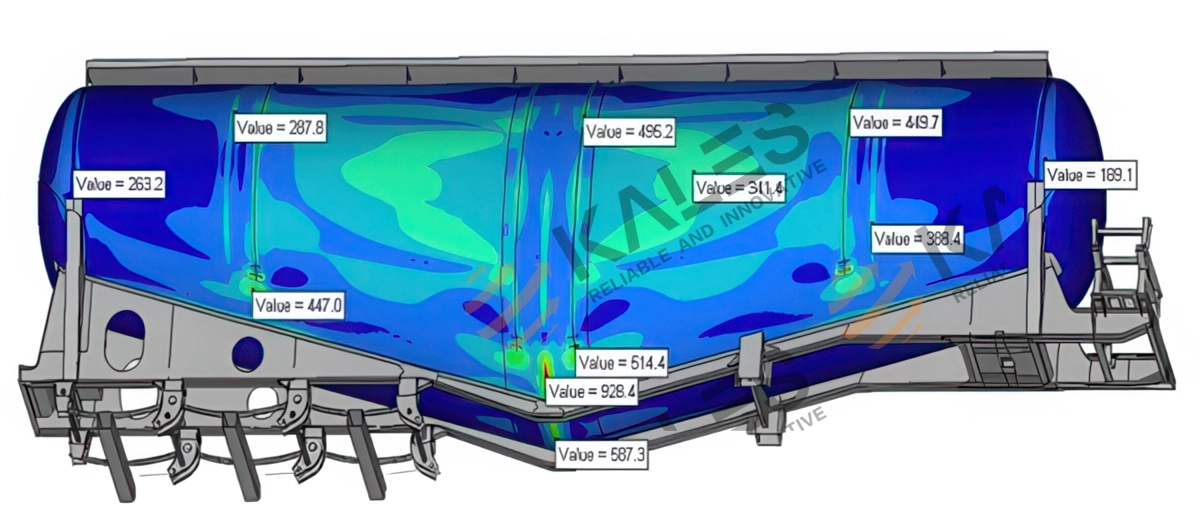

🔧 Step 1: Design – CAE Simulation for Maximum Structural Integrity

We don’t rely on “empirical estimates.” We utilize advanced 3D modeling and CAE (Computer-Aided Engineering) mechanical simulations to validate every structural component before production begins.

- Steeper Tank Angle Design: Our design exceeds industry standards by 2–3°, ensuring smoother material flow and significantly faster discharge rates.

- Optimized Frame Layout: Stress analysis informs the skeletal design to prevent cracking and deformation under heavy loads.

- Low Center of Gravity (C.G.): A refined chassis structure lowers the C.G., providing superior anti-rollover stability on rough terrain.

✂️ Step 2: CNC Cutting & Forming – Precision Defines Lifespan

- T700 High-Strength Steel: We use premium T700/Q345B steel, laser-cut to a tolerance of ≤ 0.01mm. This creates mirror-smooth edges that maintain 100% material integrity.

- Advanced CNC Rolling: The tank body is formed in a single pass, eliminating the hammering and internal stress that cause structural weak points in lesser trailers.

- Framed Assembly Platform: Ensures precise alignment of tank sections, guaranteeing a perfectly straight and true tank body.

🔥 Step 3: Robotic Welding – The Invisible Craftsmanship

We utilize fully automated robotic welding technology to ensure the tank can withstand high pressure:

- Single-Sided Welding, Double-Sided Forming: Creates deep, consistent penetration for maximum seam strength.

- Flawless Welds: Uniform seams that are completely free of porosity or slag inclusions, critical for pressure vessel safety.

- Even Stress Distribution: Prevents localized stress points that lead to fatigue and cracking over time.

⚙️ Step 4: Chassis Alignment – Eliminating Trailer Sway

A common driver complaint with cheap trailers is a “swaying” or “wobbling” sensation. Kales performs meticulous chassis and kingpin alignment after the tank is mounted.

Benefit: A perfectly centered C.G. for predictable, safe handling on highways and mining roads.

💨 Step 5: The “Heart” of the System – Air Compressor & Discharge

The efficiency of a pneumatic trailer relies on its power source and internal design:

- Top-Tier Power Unit: We equip our trailers with renowned Weichai Diesel Engines and Bohai/Fuda Air Compressors (12m³ double-cylinder) to ensure stable air pressure output.

- High-Speed Discharge: An enlarged outlet combined with a high-angle fluidized bed achieves discharge speeds up to 1.5 tons per minute.

- Low Residual Rate (<0.3%): Our “No-Dead-Corner” tank design ensures you deliver more product and maximize profit on every load.

🎨 Step 6: Protective Coating – Marine-Grade Protection

- Polyurethane Powder Coating: Phosphate-free and heavy-metal-free application.

- 120μm+ Thickness: Our coating thickness reaches H-Grade (Marine Standard), ensuring superior resistance to salt spray and humidity.

- Long-Lasting: Proven to withstand 5–8 years without fading or peeling in tropical climates.

🔍 Step 7: Quality Control – Rigorous Pressure & Road Testing

Every cement bulker trailer must pass a rigorous QC inspection before shipping:

- Air Tightness Test: High-pressure testing to ensure zero leaks.

- Discharge Efficiency Test: Verifying speed and residue rates.

- 30 km/h Cornering Stability Test: Ensuring anti-rollover safety.

If it doesn’t pass, it doesn’t ship. Period.

✅ Summary: What Defines a Superior Bulk Powder Tanker?

| Performance Metric | The Kales Engineering Solution |

|---|---|

| Fast Discharge Speed | High-angle tank + Bohai Compressor + optimized fluidized bed. |

| Low Residue Rate | “No-dead-corner” internal structure + optimized airflow. |

| Durability | T700 High-strength steel + robotic welding. |

📩 Ready to Upgrade Your Fleet?

Kales Vehicle provides customized bulk powder transport solutions tailored to your specific logistics needs.