“Are disc brakes too fragile for heavy loads?”

“Is the upgrade really worth the investment?”

In recent years, “Disc Brakes” have become a buzzword in the logistics industry. With stricter international safety regulations, more new trucks and premium trailers are coming standard with disc brakes. However, many fleet owners still have doubts: Are they really that good? Or are they just an expensive trend?

Today, we provide a no-nonsense, technical breakdown. We will clarify the advantages, disadvantages, and determine if this investment is worth your money.

1. What is the Difference? “Clamping” vs. “Expanding”

To understand which is better, we must look at how they work.

🛠️ Drum Brakes: The Classic Standard

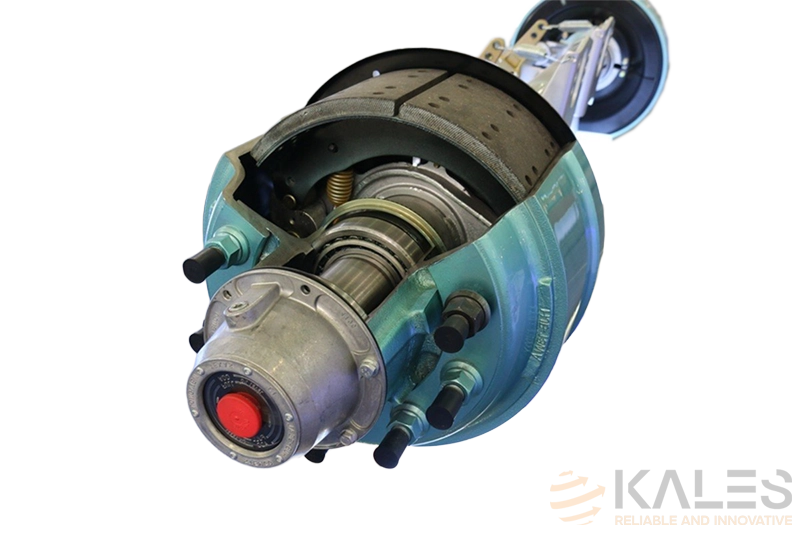

The brake drum rotates with the wheel. When braking, internal pistons push the brake shoes outward to rub against the inner wall of the drum.

Features: Low cost and traditional design. Because brake shoes are durable and provide high braking torque at the same diameter, they remain the top choice for heavy-duty off-road transport.

⚙️ Disc Brakes: The Modern Standard

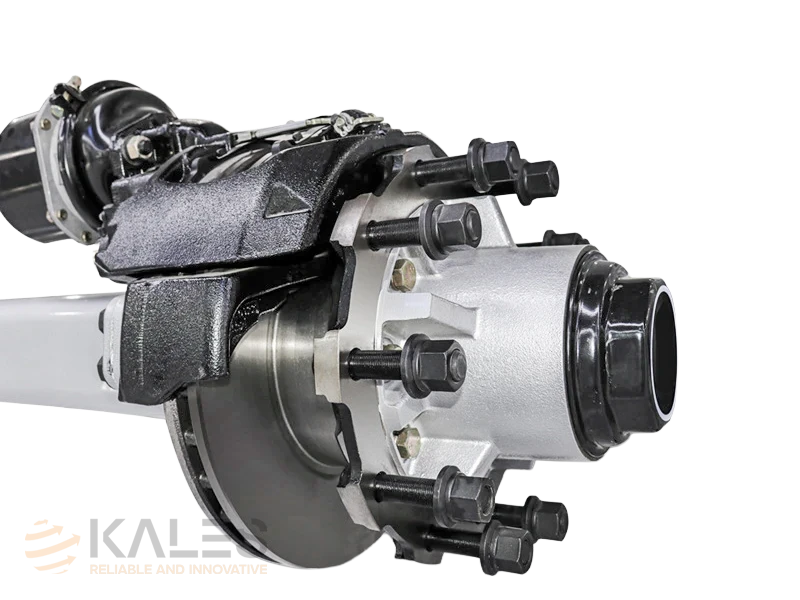

The brake disc (rotor) rotates with the tire. When braking, the caliper clamps the brake pads against the disc from both sides to generate friction.

Features: Rapid development. They are now standard on dangerous goods transport and high-end logistics vehicles worldwide.

2. Why Are Regulations Pushing for Disc Brakes? 4 Key Advantages

Compared to drums, disc brakes offer a quantum leap in safety:

1. Faster Response (Essential for ABS/EBS)

Disc brakes respond instantly, allowing for high-frequency braking actions. This makes them perfectly compatible with ABS (Anti-lock Braking System) and EBS (Electronic Braking System). On wet roads, this prevents jackknifing and side-slipping effectively.

2. Resists “Heat Fading” & Stable Pedal Feel

Drum Brake Pain Point: Under continuous braking, the drum heats up and expands (diameter increases). The brake shoes can lose contact with the drum surface, causing brake failure (Heat Fade).

Disc Brake Advantage: Excellent heat dissipation. Even if the disc expands due to heat, it expands in thickness, not away from the pads. Braking force remains stable, and pedal travel does not increase dangerously.

3. Balanced Braking Force (No Veering)

Drum brakes have a “self-energizing” effect which can lead to uneven braking force between left and right wheels. Disc brakes provide linear and equal braking force on both sides, keeping the vehicle stable during emergency stops.

4. Visual Maintenance & Automatic Adjustment

Disc brakes come with automatic gap adjustment mechanisms, reducing manual labor. Brake pad thickness is visible without dismantling the wheel hub, eliminating “hidden wear” risks.

3. The Financials: TCO (Total Cost of Ownership) Analysis

Many truckers are scared off by the initial cost. Let’s calculate the real ROI.

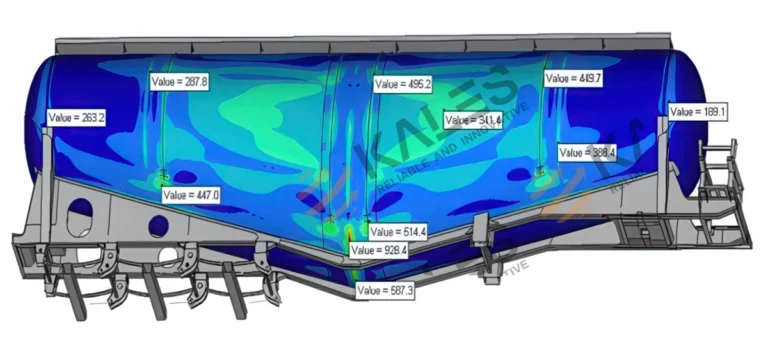

| Initial Investment | Upgrading a 3-axle trailer to Disc Brakes + Air Suspension Approx. cost increase: ~$5,500 USD |

💰 Hidden Profits (ROI):

1. Weight Savings (More Cargo):

Disc axles are lighter than drum axles. A 3-axle setup saves about 150kg.

- 📝 Calculation: Based on 150,000 km/year operation:

- Extra cargo revenue can amount to ~$1,000+ USD per year.

- In 3 years, you earn back ~$3,000 USD just on weight.

2. Maintenance Savings (Less Downtime):

Faster Changes: Disc pads take 30 mins to change; Drums take half a day. Time is money.

Tire Life: Disc brakes + Air suspension ensure even tire wear. Saving 20% on 22 tires/year saves at least ~$800 – $1,200 USD/year.

Conclusion: While the upfront cost is higher, through fuel savings, extra cargo, and tire longevity, you typically break even in 2-3 years, while enjoying superior safety.

4. The “Enemies” of Disc Brakes: Know the Limitations!

Disc brakes are advanced, but they require proper usage.

⚠️ 1. Lower Absolute Braking Torque

At the same size, drum brakes provide higher absolute stopping torque. For severely overloaded vehicles, drums are still “stronger.”

Solution: Disc brakes MUST be used with auxiliary braking systems (Retarders/Engine Brakes). Relying solely on friction brakes for heavy loads will wear them out quickly.

❌ 2. Fatal Mistake: Thermal Shock (Water Cooling)!

This is the disc brake’s biggest weakness.

- Physics (Quenching Effect): Brake discs are cast metal. If a red-hot disc (400°C+) is suddenly sprayed with cold water (a common habit in some regions), it will shrink instantly and crack or shatter.

- Mud & Dirt: In muddy mining sites, gravel can get trapped in the open caliper, acting like sandpaper. Use drum brakes for construction sites.

5. Avoid Pitfalls: Matching Tractor & Trailer

If you feel a “pushing” sensation or “soft brakes,” the issue might not be the disc brakes, but a mismatch between the Tractor and Trailer braking systems.

💡 Expert Note: Mixing an old Drum Brake Truck with a new Disc Brake Trailer often causes response lag. Consult a professional for valve adjustment.

6. Practical Guide: Daily Use & Maintenance

1. The 3 Golden Rules

- 🚫 NO Water Cooling: Do not spray water on hot discs. They will crack.

- 👀 Visual Check: Inspect the open caliper structure daily for debris or cracks.

- 💧 Drain Air Tanks: Drain water from air tanks every 2 weeks to protect the valves.

2. Maintenance Standards

⚠️ The Red Line: 2mm

Kales experts advise: When brake pad friction material wears down to 2mm, replace immediately!

Also replace if you see: Glazing (shiny surface), Cracks, or Oil contamination.

🛠️ Axle Maintenance Tip

Axle Care: Don’t forget to grease the axle hubs annually.

💡 Want less hassle? Choose Kales 13-Ton Disc Brake Axles. They come with specialized long-life lubrication, offering longer maintenance intervals and better stability.

7. Summary: Who Should Switch?

Should you upgrade? Find your scenario:

- ✅ Highly Recommended: Standard Load Transport, Express Logistics, Dangerous Goods, High-Value Cargo (Electronics/Cold Chain).

- ⛔ Use Caution: Severe Overloading, Mining/Off-road sites, or drivers who refuse to use Retarders.

❓ FAQ

Q: How often should I change disc brake pads?

A: It depends on usage. For standard highway logistics, front axle pads last 100k-150k km, trailer pads 80k-120k km. Using a retarder can extend this to 200k+ km.

Q: Can I put disc brakes on leaf spring suspension?

A: Technically yes, but Air Suspension is strongly recommended (and often legally required) with disc brakes to reduce vibration damage to the precise caliper mechanisms.

Q: I see small cracks on the rotor. Should I change it?

A: Hairline heat cracks on the surface are normal. However, if cracks extend to the edge or are deeper than 1.5mm, replace the rotor immediately to prevent shattering.

Need a specific trailer configuration or quote?

Our team can calculate the TCO for your specific route.

📱 Chat with Kales Experts (WhatsApp)