A comprehensive evolution of anti-corrosion & environmental compliance. Learn how to distinguish “True Protection” from “Superficial Shine.”

📖 Technical Index

- 1. The 5 Mainstream Coating Systems

- 2. Deep Dive: E-coat & Powder Coating

- 3. Standards: Surface Prep & Thickness

- 4. 7 Major Failure Risks (Full Analysis)

- 5. Material Specifics (Steel vs. Aluminum)

- 6. Lifespan & ROI Analysis

- 7. Buyer’s Guide: “4 Looks, 1 Ask”

- 8. 2025 Selection Guide Appendix

I. Introduction: It’s More Than Just “Face Value”

Many people believe that painting a semi-trailer is simply a matter of spraying on a few coats of topcoat.

But in reality, the anti-corrosion system of a modern semi-trailer has evolved from primitive manual brushing to sophisticated industrial processes like Cathodic Electrodeposition (E-coat) + Intermediate Coat + Liquid Baking Paint or Electrostatic Powder Coating. A scientifically engineered paint system allows a high-strength steel chassis to serve safely for 15 years under harsh salt spray, snow-melt chemicals, and mud. Conversely, a low-quality coating can lead to structural rust-through in as little as 3 years.

Against the backdrop of global “Carbon Neutrality” goals and stricter environmental regulations (such as EU REACH), paint is no longer just a cosmetic feature. It is the bottom line of safety, an environmental responsibility, and a core variable in the Total Cost of Ownership (TCO).

This guide will take you systematically through the five mainstream coating processes—Manual Brushing, Standard Liquid Spray, Cathodic E-coat, Liquid Baking Paint, and Powder Coating. We will analyze their principles, standards, typical failure risks, and life-cycle impact to help you distinguish between “True Protection” and “Superficial Shine.”

II. Comparison of the Top 5 Coating Systems

| Process Type | Principle | VOC Emissions | Utilization | Typical Application |

|---|---|---|---|---|

| Manual Brushing | Hand-applied alkyd paint | High | <30% | Small workshops, non-standard repairs |

| Standard Liquid Spray | Air gun spray (Epoxy/PU) | Med/High | 40–60% | Mainstream chassis beams |

| Cathodic E-coat (E-coat) | Electrical deposition in tank | Very Low | >95% | Full chassis (including inner cavities) |

| Liquid Baking Paint | High-temp cured topcoat | Medium | 50–70% | High-end finish, Cabins |

| Powder Coating | Electrostatic adhesion + Melting | Zero VOC | >98% | Box bodies, Fenders, Toolboxes |

✅ 2025 Industry Trends:

- Chassis: E-coat has become the standard mainstream solution for high-end trailers.

- Upper Body/Accessories: Powder coating is rapidly replacing liquid paint, balancing environmental compliance with physical performance.

III. Deep Dive: E-coat, Liquid Baking & Powder Coating

(A) Cathodic Electrodeposition (E-coat)

- Principle: The entire chassis is submerged in an electrified tank. Paint particles are deposited evenly onto the metal surface, reaching inner cavities and weld seams that spray guns miss.

- Advantage: 360° coverage, Adhesion Grade 0 (GB/T 9286), Salt Spray Resistance ≥1000 hours with no red rust.

- ⚠️ Limitations:

- High capital investment; strictly for conductive metals.

- Poor UV Resistance: E-coat (Epoxy resin) chalks when exposed to sunlight. It must be covered with a UV-resistant topcoat for outdoor use.

(B) Liquid Baking Paint (High-Temp Cured)

- Principle: Polyurethane or acrylic resins are cured in baking ovens at 120–140℃, creating a dense cross-linked structure.

- Advantage: High gloss, excellent color retention (no chalking for 5 years), Pencil Hardness ≥H, resistant to minor scratches.

- Best For: High-end export trailers, Reefer units, and Aluminum box exteriors.

(C) Electrostatic Powder Coating

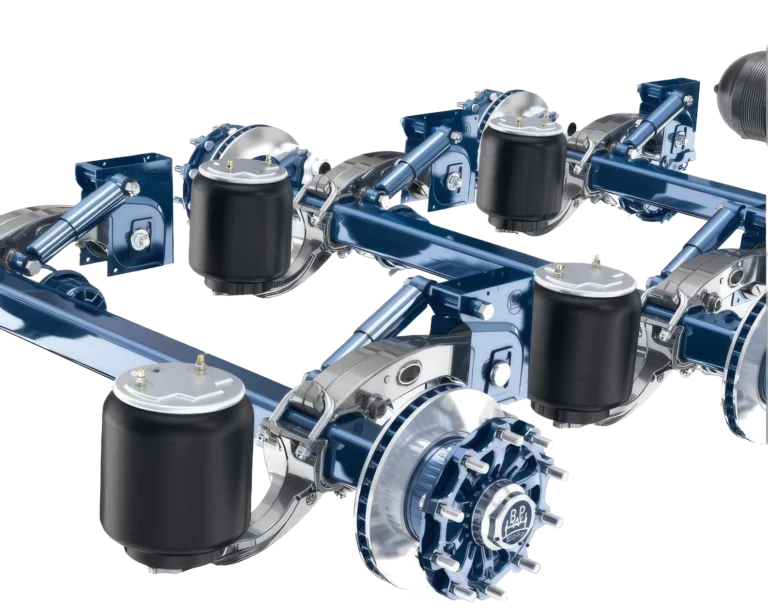

Kales flatbed trailer parts receiving powder coating after e-coat for long-lasting, eco-friendly surface protection.

- Principle: Negatively charged powder is sprayed onto a grounded workpiece, then melted and cured at 180–200℃.

- Core Advantages:

- Zero VOCs: Compliant with strict national and international environmental laws.

- High Efficiency: >98% utilization (overspray is recycled).

- Dense Coating: One-pass application, no sagging (runs), no pinholes from solvent evaporation.

- Mechanical Strength: Impact resistance ≥50 kg·cm, excellent stone-chip resistance.

- ⚠️ Thickness Control: Optimal thickness is 60–100μm.Note: Excessive thickness (>120μm) makes the coating brittle, prone to cracking under impact, and causes severe “orange peel.”

- Resin Types:

- Epoxy: Strong adhesion but poor UV resistance (Inner parts only).

- Polyester (TGIC/HAA): Excellent weatherability, suitable for outdoor visible parts (Box bodies, fenders).

IV. Construction Standards & Acceptance Criteria

(A) Surface Preparation: The Foundation (70% of Quality)

- Manual Brushing: St2 (Visual removal of floating rust) → Not Recommended.

- Standard Spray/Powder: Sa2.5 Sandblasting (GB/T 8923.1). The surface must present a uniform metallic luster with a roughness of Rz=40–70μm (to increase anchor points).

- E-coat: Degreasing → Phosphating → Multi-stage Pure Water Rinsing (Cleanliness ISO 8502-9 Class 2).

- Aluminum Parts: Must undergo Chrome-free conversion (e.g., Zirconium/Silane) or compliant chromating. Simple acid washing or standard phosphating is strictly prohibited.

(B) Thickness Standards (Reference QC/T 934-2013)

| Process | Primer | Intermediate | Topcoat | Total DFT |

|---|---|---|---|---|

| Standard Spray | Epoxy Zinc (60μm) | Epoxy Iron (60μm) | PU (50μm) | ≥170μm |

| E-coat + Baking | E-coat (20-25μm) | Epoxy (40-60μm) | Baking (40-50μm) | ≥110μm |

| Powder Coating | — | — | Polyester (60–100μm) | Single Layer |

💡 Key Insight: Why is “thinner” Powder/E-coat better?

Quality is not just about thickness, but about density and cross-linking degree. High-temperature cured powder or E-coat forms a molecular cross-link density far higher than air-dried liquid paint, effectively blocking water and oxygen penetration even at lower thicknesses.

V. 7 Major Paint Failure Risks (Deep Analysis)

🔴 Risk 1: Poor Surface Prep = Adhesion Loss

Mechanism: 70% of adhesion relies on substrate surface status. Oil, scale, or insufficient roughness prevents anchoring.

Symptoms: Blistering, peeling sheets (especially at welds); Cross-cut test fails (≥ Grade 2); Red rust within 48h of salt spray.

Prevention: Mandate Sa2.5 Sandblasting; Use white gloves to check cleanliness upon delivery.

🔴 Risk 2: Wrong Primer = No Electrochemical Protection

Mechanism: Zinc-rich primers protect steel sacrificially. If zinc content is low (<60%) or cheap iron-red primer is used, electrochemical protection is lost.

Data: Genuine Zinc-rich (≥80%) resists salt spray >500h; Fake Zinc-rich (<40%) rusts in 72h.

Prevention: Contract must state “Dry Film Zinc Content ≥80%” and demand lab reports.

🔴 Risk 3: Improper Curing

Symptoms: Baking paint chalks in 6 months; Powder coating cracks (over-baked) or peels (under-baked); E-coat rusts early due to thinness in cavities.

Prevention: Factories must use Oven Temperature Trackers to verify the curing curve; Powder must be stored dry (<60% humidity).

🔴 Risk 4: Incompatible Coating System

- Typical Error A: E-coat primer + Topcoat without sanding/intermediate coat. Result: Topcoat peels off the slick E-coat.

- Typical Error B: Aluminum + Zinc-rich primer. Result: Major Mistake! Zinc cannot protect aluminum and causes a saponification reaction, leading to total detachment.

Solution: Use Epoxy Iron Cloud intermediate coats (wet-on-wet) for steel; Specialized Epoxy primer or direct Polyester powder for aluminum.

🔴 Risk 5: Design “Dead Zones”

Problem: Closed beams without drain holes (water accumulation); Gaps between cross members (capillary action).

Prevention: Drill Φ8–10mm drain holes in closed beams; E-coat solves cavity issues; Standard trailers need internal cavity wax.

🔴 Risk 6: Severe Environment

Problem: Northern regions (snow melt agents), Coastal (salt spray), Mining (acidic dust).

Recommendation: Mandatory E-coat + High DFT (≥160μm). Regular chassis washing.

🔴 Risk 7: Improper Use & Maintenance

Mistake: Using high-pressure water guns directly flushing weld seams. Ignoring scratches.

Correct Practice:

- Use low-pressure water for chassis cleaning.

- Crucial: Small area scratches must be spot-repaired immediately using zinc-rich touch-up paint to prevent rust spread.

- Perform annual inspections of key stress points.

VI. Material-Specific Recommendations

| Material | Recommended Process | TABOO (Do Not Do) |

|---|---|---|

| Carbon Steel (Q355/Q700) | E-coat + Liquid Baking (Chassis) Powder Coating (External Parts) |

Avoid acid wash instead of sandblasting. |

| Aluminum Alloy | Chrome-free Prep + Polyester Powder OR Zirconium + Specialized Paint |

Strictly No Zinc-rich primers. No direct E-coat (requires special process). |

| Stainless Steel | Usually unpainted. If needed: Adhesion Promoter + Topcoat. |

Avoid sanding that destroys the dense passive film. |

VII. Lifespan & ROI Analysis (Real Data)

| System | 5-Year Status | 10-Year Status | Est. Life |

|---|---|---|---|

| Manual Alkyd | Major Rust | Structure Loss >30% | ≤6 Years |

| Standard Spray | Local Floating Rust | Weld Corrosion | 10–12 Years |

| E-coat + Baking | Almost No Rust | Minor Topcoat Aging | 15–18 Years |

| Powder Coating | No Fading/Peeling | Intact | 12–15 Years |

E-coat + Baking paint may cost $1,200–$1,800 more per trailer initially compared to standard spray, but it extends service life by 5+ years and significantly increases resale value. Powder coating has high initial investment but lower long-term operating costs due to Zero VOC and high utilization.

VIII. Buyer’s Checklist: “Four Looks, One Ask”

- Look at the Inner Cavity: Is it a uniform gray/black? (Sign of E-coat; spray guns can’t reach here).

- Look at Box/Parts Coating: Is the edge wrapping complete and thick? (Sign of Powder Coating).

- Check Hardness: Scratch lightly with a key. No mark? = Baked/Powder. Deep white scratch? = Air-dried paint.

- Check Welds & Edges: Is there full coverage? Manual paint often leaves “shadow zones.”

- ASK DIRECTLY:

- “Is the chassis fully immersion E-coated?”

- “Is the aluminum pre-treatment Chrome-free?”

- “Is powder thickness controlled under 100μm?”

Conclusion: Paint is the “Invisible Brand” of Quality

Today’s semi-trailer painting has gone far beyond aesthetics. E-coat protects the chassis safety line, Baking Paint offers high-end texture, and Powder Coating delivers green durability.

Choosing the right paint isn’t about finding the “most expensive” option, but matching the system to your operating environment. A highway logistics van requires a different strategy than a mining dump trailer.

At Kales Vehicle, we adhere to a “Customized for Application” philosophy:

- ✅ No Blind Upgrades: Precise powder thickness control avoids brittleness.

- ✅ Scientific Protection: We prevent rookie mistakes like using zinc primer on aluminum.

- ✅ Transparent Delivery: From material selection to thickness reports, complete transparency.

“Check the paint before you buy the truck. Good paint is worth its weight in gold.”

With the same steel quality, a scientific anti-corrosion system—Chassis E-coat, Body Powder, Scientific Prep—is what defines a truly high-end semi-trailer.

Appendix: 2025 Coating Selection Guide (Kales Logic)

| Customer Need | Recommended Solution | Kales Service Feature |

|---|---|---|

| Economy Logistics (Short haul/Inland) | Sa2.5 Sandblast + Epoxy Zinc + PU (DFT≥160μm) | Strict material standards, refusing “shiny surface” traps. |

| Efficient Long-Haul / Cold Chain | Full Chassis E-coat + Intermediate + Baking Paint | Provides coating test reports, supports 3rd party inspection. |

| Environmental Priority / Export | Chassis E-coat + Body Powder Coating | Zero VOC process, meets international certifications. |

| Aluminum Upper Body Users | Chrome-free Prep + Polyester Powder | Specialized prep + Weather-resistant formula to avoid galvanic/saponification issues. |

🌍 Kales Vehicle —— Not just building trucks, but understanding your operation.

From steel to paint, design to delivery, we turn every investment into real value.