In the heavy transport industry, efficiency is king. Whether you call it a pneumatic dry bulk trailer, a cement bulker, or a “silobas,” choosing the right equipment and operating it correctly is crucial for profitability. As a leading manufacturer exporting to Africa, Latin America, and Central Asia, Kales Vehicle Co., Ltd. presents this comprehensive guide to mastering your bulk powder tanker semi trailer.

Kales 3-axle bulk powder tanker semi trailer for cement transport ready for export.

1. Why Choose Kales Pneumatic Dry Bulk Trailers?

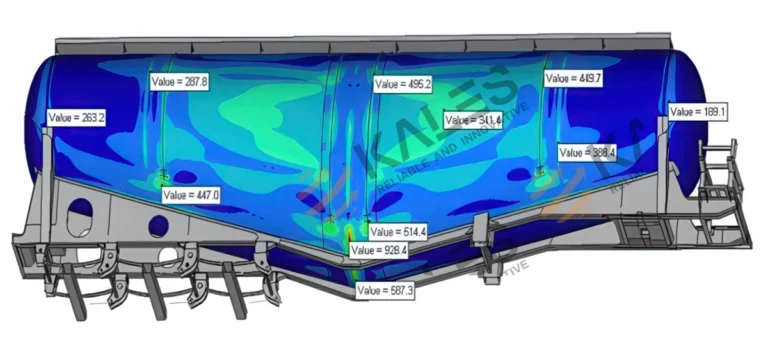

Designing trailers for rough terrain requires more than just steel; it requires engineering precision. Kales trailers are built to withstand the harsh road conditions of mining regions while delivering high-speed unloading.

- ⚡ Fast Unloading Speed: Achieves 1.2–1.5 tons/minute, significantly reducing waiting time at the construction site.

- 📉 Ultra-Low Residue: Our advanced fluidized bed design ensures a residue rate of <0.1%, saving you material costs on every trip.

- 🛠️ World-Class Components: We use globally trusted brands for easy maintenance:

- Diesel Engines: Reliable Weichai engines for consistent power.

- Air Compressors: High-performance Bohai or Suzhou compressors (12m³ dual-cylinder).

- Braking: Genuine WABCO braking systems for safety.

- 🌍 Reinforced Chassis: Specially strengthened sub-frames and suspension systems designed for African and Central Asian road conditions.

2. Selecting the Right Bulk Tanker Configuration

Choosing between a V-shape, Cone-shape, or Tipper depends entirely on your cargo.

🚛 Type A: Horizontal “V-Shape” Cement Trailer

Best for: Cement, Fly Ash, Lime Powder.

- Pros: Low center of gravity provides superior stability on highways. Simple internal structure allows for large capacity (up to 85m³).

- Cons: Not suitable for coarse materials that don’t fluidize well.

🚀 Type B: Vertical “Cone” Tanker

Best for: Granules, Fertilizer, Coarse materials.

- Pros: Gravity-assisted discharge ensures clean unloading of heavier particles.

- Cons: Higher center of gravity requires careful driving on curves.

🆙 Type C: Tipper (Lift-Type) Powder Tanker

Best for: Food-grade Flour, PTA, Pharmaceutical Powders.

- Pros: Zero residue makes it ideal for hygiene-sensitive cargo. Easy to clean internally.

- Cons: Requires a flat, stable site for lifting to prevent tipping over.

3. Power Source: Diesel Engine vs. PTO

When ordering your Kales cement trailer, you must decide how to power the air compressor.

| Feature | Independent Diesel Engine | PTO (Power Take-Off) |

|---|---|---|

| Flexibility | High. Works with ANY truck head. Ideal for logistics companies with mixed fleets. | Low. Must be paired with a specific truck head equipped with a PTO gearbox. |

| Weight | Heavier (Adds approx. 500kg). | Lighter (Saves fuel during empty return trips). |

| Maintenance | Requires separate engine oil/filter changes. | Low maintenance (uses truck engine power). |

1

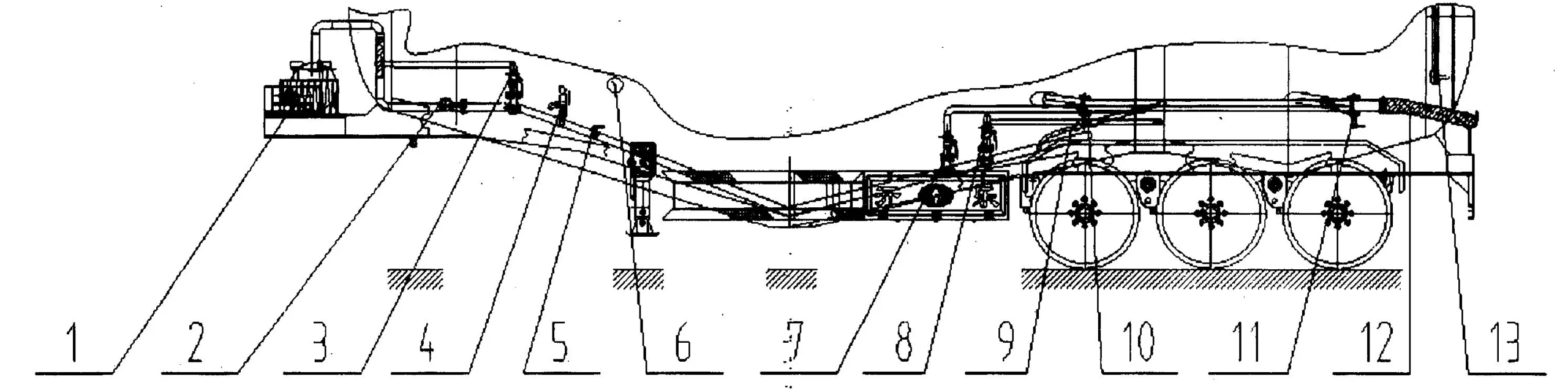

- Air Compressor、2. Check Valve、3. Front Air Chamber Inlet Valve、4. Safety Valve (0–0.3 MPa)、5. External Air Source、6. Pressure Gauge、7. Middle Air Chamber Inlet Valve、8. Rear Air Chamber Inlet Valve、9. Secondary Blow Valve、10. Front Compartment Discharge Butterfly Valve、11. Rear Compartment Discharge Butterfly Valve、12. Discharge Hose

4. Standard Operating Procedure (SOP) for Safe Unloading

Follow this step-by-step guide to ensure safety and prevent damage to the fluidization canvas.

⚠️ Critical Safety Rules

MOISTURE WARNING: Never allow water into the tank or air lines. Wet cement creates concrete blockages that can ruin the tank.

PRESSURE HAZARD: Never open the manhole cover while the pressure gauge reads above 0 MPa.

Step 1: Start-Up

- Connect the discharge hose to the silo inlet securely.

- Close the Pressure Relief Valve and Discharge Butterfly Valve. Open the Air Inlet Valves.

- Start the Weichai diesel engine.

- Adjust the hand throttle to the rated RPM. (Target: Keep Air Compressor at 850–1000 RPM. Do not over-rev!)

- Wait until tank pressure builds to 0.2 MPa.

Step 2: Unloading

- Open the Secondary Blow Valve (Assist Valve) to clear the discharge pipe.

- Slowly open the main Discharge Butterfly Valve.

- Monitor the pressure. If it drops rapidly, the tank is emptying.

Step 3: Cleaning & Shutdown

- When pressure drops to 0.15–0.10 MPa, alternate opening and closing the front/rear inlet valves. This “sweeping” action clears residue.

- Stop the engine. Open the pressure relief valve to release all remaining air before disconnecting hoses.

5. Troubleshooting: How to Unblock a Cement Tanker Pipe

A clogged discharge hose is a nightmare for drivers. If your pressure gauge spikes (>0.25 MPa) and discharge stops, follow this emergency procedure.

The “Pulse” Technique (Emergency Unblocking)

- STOP: Do not increase the throttle; this will pack the powder tighter.

- CLOSE: Close the main Discharge Butterfly Valve.

- BLAST: Open the Secondary Blow Valve fully to blast air through the hose.

- PULSE: Quickly open and close the Discharge Butterfly Valve. The sudden pressure bursts often dislodge the blockage.

- MANUAL: If this fails, stop the engine, release ALL pressure, and physically check the rubber hose. A hard section indicates the clog.

6. Maintenance Guide for Rough Roads

To extend the life of your dry bulk trailer in Africa or Central Asia, pay attention to these often-overlooked areas.

✅ Chassis & Suspension

- U-Bolts: Retighten leaf spring U-bolts every 5,000 km. Loose bolts are the #1 cause of suspension failure on dirt roads.

- Cushion Pads: Inspect the rubber pads between the tank body and chassis. Worn pads lead to metal-on-metal stress cracks.

✅ Fluidization System

- Canvas Life: The breathable belt inside the tank usually lasts 1–2 years. If unloading slows down, replace it.

- Water Separator: Drain the air compressor tank daily. Moisture is the enemy of the fluidization belt.

Ready to Upgrade Your Fleet?

Kales Vehicle Co., Ltd. delivers durable, high-performance transport solutions tailored to your market. Contact us today for technical diagrams and a custom quote.