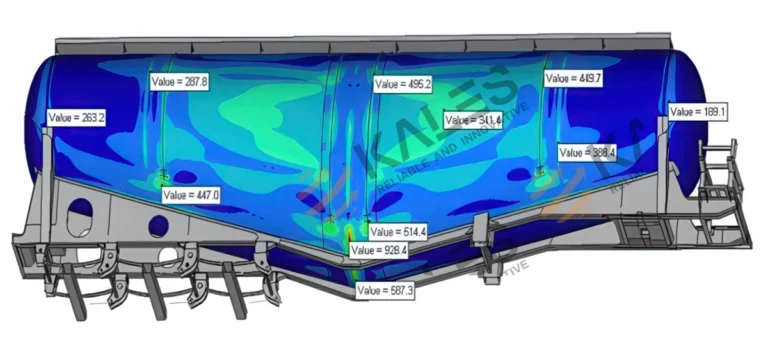

Proper lubrication is one of the most critical yet often overlooked aspects of Kales semi-trailer maintenance. Regularly greasing the right components with the correct lubricants not only ensures smooth operation but also prevents premature wear, enhances road safety, and significantly extends your trailer’s service life.

In this guide, we’ll walk you through everything you need to know about lubricating your Kales semi-trailer—from recommended grease types and lubrication intervals to best practices that keep your fleet running efficiently.

Why Lubrication Matters for Your Kales Semi-Trailer

Friction is the silent enemy of heavy-duty trailers. Without adequate lubrication, you risk:

- Accelerated wear on moving parts

- Heat buildup in axle bearings and joints

- Component seizure or unexpected failure

- Reduced fuel efficiency due to increased rolling resistance

- Increased Safety Risks: Especially in critical systems like brakes and suspension.

By following a structured Kales semi-trailer lubrication schedule, you protect your investment, reduce repair costs, and avoid costly roadside breakdowns.

Recommended Lubricants for Kales Semi-Trailers

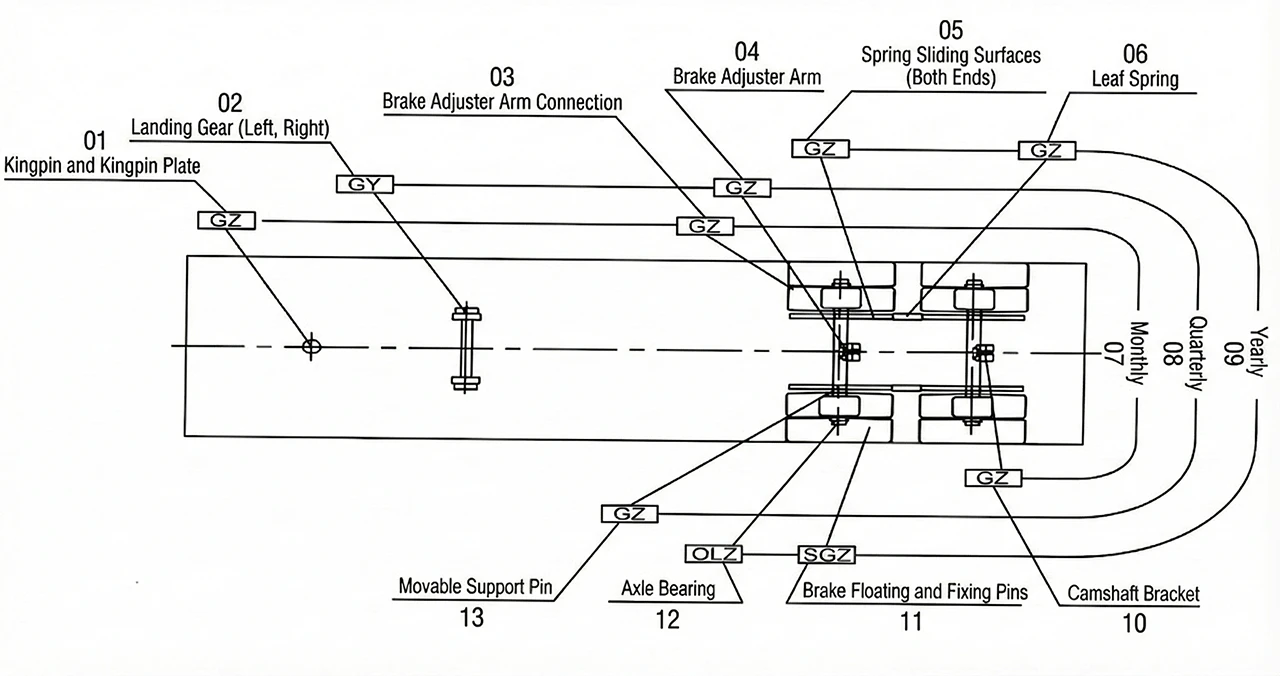

Kales specifies three primary grease types. Using the correct lubricant is essential. Below is a comparison of the Chinese Standards (found in your manual) and their International Equivalents for global maintenance teams.

| Code | Lubricant Name | Standard (China) | International Equivalent (Ref.) | Recommended Use Case |

|---|---|---|---|---|

| GZ | Calcium-Based Grease | ZG-4 | NLGI #2 (Calcium) | General-purpose, moderate temps, chassis points |

| QLZ | Automotive Universal Lithium Grease | GB5671-85 | NLGI #2 (Lithium EP) | High-load, multi-point applications (Axles) |

| SGZ | High-Temperature Grease No. 4 | ZN6-4 | NLGI #3 (High Temp) | High-heat zones (e.g., brake pins) |

Lubrication Points Key:

01: Kingpin & Plate | 02: Landing Gear | 03-04: Brake Adjusters | 05-06: Leaf Springs & Slides

10: Camshaft Bracket | 11: Brake Pins | 12: Axle Bearing | 13: Movable Support Pin

Kales Semi-Trailer Lubrication Schedule

Below is the official maintenance chart detailing daily, monthly, and annual greasing points.

Lubrication Frequency Chart

| Lubrication Point | Daily | Monthly | Annually | Recommended Lubricant |

|---|---|---|---|---|

| Kingpin & Fifth Wheel Plate | ✓ | Calcium-Based (ZG-4 / NLGI #2) | ||

| Landing Gear (Support Device) | ✓ | Calcium-Based (ZG-4 / NLGI #2) | ||

| Brake Slack Adjuster | ✓ | Lithium Grease (GB5671 / NLGI #2 EP) | ||

| Slack Adjuster Linkage | ✓ | Calcium-Based (ZG-4 / NLGI #2) | ||

| Leaf Spring Pins & Slides | ✓ | ✓ (Ends) | Calcium-Based (ZG-4 / NLGI #2) | |

| Brake Camshaft Bracket | ✓ | Calcium-Based (ZG-4 / NLGI #2) | ||

| Axle Wheel Bearings | ✓ | Lithium Grease (GB5671 / NLGI #2 EP) | ||

| Container Twist Lock Pins | ✓ | Calcium-Based (ZG-4 / NLGI #2) |

Lubrication Best Practices

✅ DO:

- Use clean equipment: Wipe grease fittings (zerks) before attaching the gun to prevent forcing dirt inside.

- Purge old grease: Apply new grease until you see fresh grease purging from the joint to remove contaminants.

- Log it: Record all maintenance in your fleet log for compliance and warranty purposes.

❌ DON’T:

- Don’t mix grease bases: Stick to one type or thoroughly clean the component before switching.

- Don’t over-pressurize sealed bearings: This can blow out the seals and invite contamination.

- Don’t ignore winter needs: Cold temperatures thicken grease. Ensure your lubricant is rated for your operating temperature.

Frequently Asked Questions (FAQ)

How often should I grease the Kingpin on a Kales Trailer?

The Kingpin and Kingpin Plate are high-friction areas that carry the trailer’s weight. Kales recommends greasing these daily or prior to every new coupling to prevent grinding and uneven wear.

What is the best grease for trailer axle bearings?

For axle bearings (Point 12), use a high-quality Automotive Universal Lithium Grease (NLGI #2 EP). This resists high temperatures and heavy loads better than standard chassis grease.

Why do my trailer brakes squeak even after greasing?

Squeaking can occur if the Camshaft Bracket or Brake Pins are dry. Ensure you verify points 10 and 11 on the diagram. If greased and still noisy, check for worn linings or glazed drums.

Final Thoughts: Lubrication = Reliability

For fleet managers and owner-operators, consistent lubrication is non-negotiable. By adhering to Kales’ recommended grease types and maintenance intervals, you ensure driver safety, regulatory compliance, and maximum ROI.

🔧 Need technical support or spare parts? Contact the Kales Service Team for expert assistance!